Containment: A Must-Have in Tableting

STYL’One stands for no compromise on tabletting analysis and no compromise on user protection from early research to multilayer production scale-up.

MEDELPHARM is a high-precision engineering company manufacturing research and development (R&D) tablet presses and providing innovative solutions for powder analysis and formulation.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

MEDELPHARM is a specialist in the development, design, and manufacture of research and development (R&D) tablet presses and compaction simulators for powder compaction.

This high-precision engineering company provides intelligent tablet press technology and software development solutions for powder analysis and formulation.

MEDELPHARM focuses on the continuous development of innovative research and development presses (hardware and software), compaction simulation of industrial production cycles, powder characteriation and formulation services, compression, and material science. As compressed powders can be found everywhere, the applications encompass the pharmaceutical, cosmetics, food and nutraceuticals, chemistry & detergents, batteries & catalysts and explosives & nuclear industries.

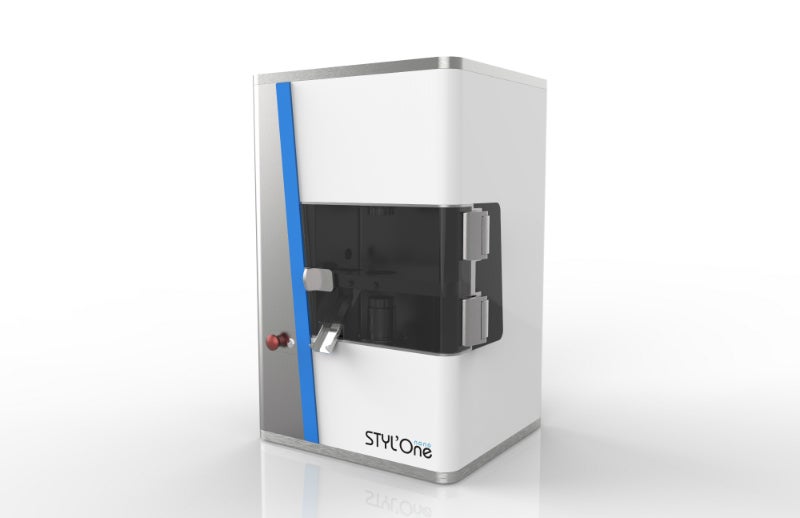

The STYL’One Nano is the revolutionary benchtop R&D tablet press for demanding formulation scientists with price performance in mind. From API/excipient characterization, analytical development to formulation feasibility assessment and optimization, develop your single-layer formulation with only a few grams of powder.

The STYL’One Evo versatile compaction simulator is a high-speed, all-in-one single and multilayer tool designed for use in tablet development from early formulation to scale-up at production speed.

The machine characterizes essential powder properties and active pharmaceutical ingredients (API). It tests their suitability by simulating industrial production cycles, typically up to 400,000 tab/hour (dwell time <2ml), with only a few grams of powder needed.

The STYL’One Evo is designed for ease-of-use, compact footprint, and offers easy exchange of B, D (EU │TSM), oversized or core rods tooling. An optional micro-dosing unit, tab-in-tab device, GMP module with weight regulation, and force feeding are just a few of the available accessories offered with production mind.

More than 250 MEDELPHARM STYL’One units have been installed worldwide.

QbD is a concept to produce a drug in a repeatable and cost-effective way. The QbD concept is in the heart of the design and development of the STYL’One R&D tablet press.

With a global trend of powders being more and more potent, MEDELPHARM makes no compromise on user protection during tableting offering multiple solutions from wash-in-place to full containment OEB 5.

Deciding on the right granulation process to meet your needs can be very material consuming. With the STYL’One Evo roller compaction simulation tool, you can identify the feasibility and impact of dry granulation directly at lab-scale with a limited amount of powder.

MEDELPHARM offers a range of training courses that are recognised by French authorities. The company aims to offer its extensive knowledge through effective training.

MEDELPHARM also offers its professional tableting instruments to various universities for training purposes so students can gain experience on current and future working methods. The company has university partnerships worldwide.

MEDELPHARM offers services such as URS definition, installation, FAT, SAT, training and support, maintenance, and calibration, as well as consumables and wear and tear parts.

MEDELPHARM distributes for France and Belgium renowned and innovative technologies in powder processing from lab scale to production, in association with partners worldwide, primarily KORSCH AG with its internationally renowned range of rotary presses.

Other collaboration partners include:

MEDELPHARM’s tableting and powder characterisation laboratory houses a team of research scientists and a range of sophisticated instrumentation dedicated to supporting clients with their product development needs. These include material characterisation, scale-up, small batch production, formulation, troubleshooting.

Innovative measuring equipment include STYL’One Nano and Evo compaction simulators, Smart Test 50, a CALEVA mini coater, a Quadro SLS multifunctional scalable lab system and a Comil U5, as an Accupyc (Micromeritics) Helium Pycnometer to measure true density, a turbula mixer, a disintegration bath and a friability tester.

Headquartered near Lyon, MEDELPHARM is a high-precision engineering company manufacturing R&D tablet presses and providing innovative solutions for powder characterisation and formulation.

Since 1985, MEDELPHARM is a specialist in tableting instruments ‘Made by people for people’, that work with high-speed and precision but at the same time are very easy-to-use. With its historical background in actual production, MEDELPHARM has a deep understanding of the R&D requirements that apply to tableting processes.

For formulation and pilot plant scientists around the world looking for assistance in powder characterisation, solid dosage formulation or production troubleshooting, MEDELPHARM can offer a comprehensive portfolio of versatile R&D presses and high-speed compaction simulators supported by a team of dedicated scientists.

Since the end of 2022, it has been a member of the international KORSCH Group, enhancing its worldwide reach.

STYL’One stands for no compromise on tabletting analysis and no compromise on user protection from early research to multilayer production scale-up.

Lubricants are often required to minimise friction between a tablet surface and the die walls during the ejection phase of the compression cycle.

Tableting has never been so easy and so powerful, from pure API characterisation to formulation assessment. Single-punch presses are ideal at formulation stage: easy to operate, easy to clean and for small amounts of API.

Underestimating complexity underlies common problems in tableting. Modified release tablets are more complex than immediate release but no tablet is simple enough to never fail.

Itraconazole (ITZ), a BCS Class II drug exhibiting low solubility (1-4ng/mL in water) requires formulation enhancement to achieve enhanced bioavailability. To tackle this problem, amorphous solid dispersions (ASDs) of ITZ in a polymer matrix (Kollidon® VA64) were produced using the Hot Melt Extrusion (HME) process.

Knowledge management based on data leads to avoid tablet defects in production and guarantee high production output. This can be undertaken right from the development stage thanks to STYL’One compaction simulators.

This free white paper presents the methodology of MEDELPHARM Science Lab to study the effects of granulation critical process parameters on product quality attributes.

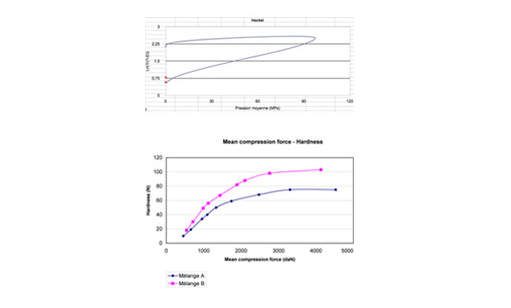

How close is the simulation offered by MEDELPHARM's STYL'One to that of a rotary tablet press? Download this free PDF document to see some test results.

Compaction simulators are a key technology allowing scientists to develop formulations and troubleshoot tablet defects.

Instrumented die is used to measure maximum die-wall pressure (MDP) and residual die-wall pressure (RDP) during powder compaction.

Amorphous solid dispersions (ASDs) have been widely used to improve the bioavailability of poorly water-soluble drugs.

This free white paper covers a brief overview of the steps for pharmaceutical product development under the quality by design (QbD) framework; introduces design of experiments (DoE) applied to formulation of tablets and gives an example of how to design piroxicam amorphous solid dispersions (ASD) tablets using DoE.

Itraconazole (ITZ) is an antifungal drug commercially available as an oral solution or more commonly as 100mg capsules. It has been reported that the bioavailability of the oral solution is only 55%.

There are numerous tablet defects: chipping, picking and sticking, cracking, lamination, and capping to name a few.

KORSCH and LB Bohle present their complementary technology at ACHEMA 2024 in Frankfurt am Main, Germany, in a shared booth. KORSCH, the global specialist in tablet press technology, complements with its innovations the processes delivered from Bohle to plan and map the entire tablet production process. Both companies offer world-class, complementary technology and have worked together on a wide range of projects involving integrated technology and process equipment trains.

Research-based manufacturer and powder compaction specialists MEDELPHARM S.A.S. will showcase its advanced tablet research solutions at the American Association of Pharmaceutical Scientists annual meeting, AAPS PharmSci 360, in Florida.

MEDELPHARM S.A.S. has successfully completed factory acceptance and particle containment testing for a high containment version of its industry-leading STYL’One Evo compaction simulator.

The X 5 is a single rotary press with a comparable footprint to the KORSCH flagship XL 400, but offers 20% more production capacity. The X 5 retains the KORSCH characteristic flexibility and quick-change design.

World-leading powder compaction simulation solutions from MEDELPHARM will form a key part of an impressive combined display of advanced pharmaceutical process technologies at the Interpack trade fair in Düsseldorf, Germany, from 4-10 May 2023.

Innovative compaction simulator technology adds early-stage material characterisation and scale-up capability to the KORSCH R&D product portfolio.

Research-based manufacturer and powder compaction specialists Medelpharm will showcase advanced tablet formulation possibilities offered by its STYL’One Nano benchtop research press platform at the upcoming Making Pharmaceuticals Ireland event in Dublin, Ireland.

The MEDELPHARM team will be present at ACHEMA 2022 in KORSCH's booth A49/A71 in Hall 3.0 for live demos of the STYL'One Nano compaction simulator.

MEDELPHARM will be present at the 13th World Meeting on Pharmaceutics, Biopharmaceutics and Pharmaceutical Technology, March 28-31, Rotterdam.

This versatile machine is built upon the flexibility and multilayer capacity of the classic STYL'One and the speed and simulation function of the STYLCAM.

MEDELPHARM’s services accompany you in formulation, powder analysis and characterisation.

MEDELPHARM provides a range of software solutions for data analysis.

The new STYL’One Nano is a revolutionary benchtop R&D press for demanding formulation and scientists with price performance in mind.

STYL’One Evo’s sophisticated design can handle complex tablet forms of up to five layers, incorporating three different powders thanks to the multi-layer module. Develop a robust multilayer formulation thanks to STYL’One Evo.

The STYL’One Nano is the revolutionary benchtop R&D tablet press for demanding formulation scientists. From API/excipient characterisation, analytical development to formulation feasibility assessment and optimisation, develop your single-layer formu

The STYL’One Evo is the most versatile compaction simulator for R&D, scale-up and production support.

MEDELPHARM's STYL'One Evo facilitates tab-in-tab formulation designs and allows them to be tested at equivalent production speeds

MEDELPHARM's STYL'One external lubrication pack is designed to deliver a consistent lubricant dose on the punches and die before filling.

MEDELPHARM's Science Lab uses its experience and knowledge to support clients at each stage of product development, from research and development to manufacturing.