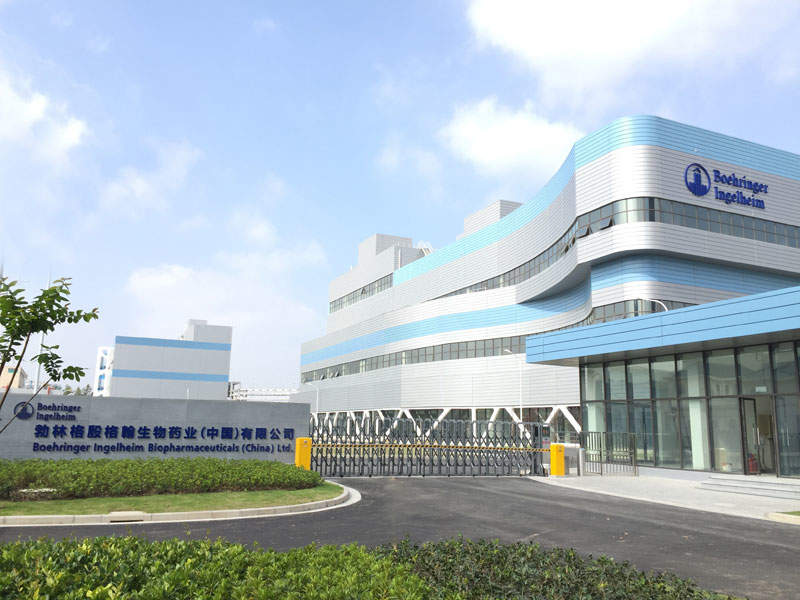

German pharmaceutical company Boehringer Ingelheim is developing a biologics manufacturing facility at the Zhang Jiang Hi-tech Park in Shanghai.

The greenfield facility will represent the company’s first venture into Asia, as well as one of the first biologics facilities established in China by a multi-national company.

A ground-breaking ceremony for the facility was held in June 2013. The first phase of construction was inaugurated in May 2017 and completed with a €70m ($76m) investment.

Compliant with current good manufacture practices (cGMP), the facility will allow Boehringer to become one of the leading contract manufacturing companies in China, focusing on the production of antibodies and recombinant proteins using mammalian cell culture technology. The facility will also provide development and clinical services.

Details of the Boehringer Ingelheim biopharmaceuticals project in Shanghai

Boehringer Ingelheim entered the Chinese market to offer customised contract manufacturing capabilities to the country. The project is supported by the Shanghai Municipal Government and the country’s 12th Five-Year-Plan (FYP), which allocated CNY12bn ($1.76bn) to the country’s biopharmaceutical industry.

From 2015 to 2020, Boehringer Ingelheim plans to invest more than €100m ($112m) towards the development of the site. It has been operating at 100l and 500l capacity since 2014. Operated under the name BioLab, activities included a workshop that enabled pilot tests for the creation of study samples and early clinical supplies.

The facility will enable Boehringer Ingelheim to operate at 2,000l capacity, with easy transfer of disposable models between various sites of the company. It will also provide both upstream and downstream process development, as well as clinical and commercial-scale manufacturing capabilities.

Design and capacities of the Boehringer Ingelheim facility in Shanghai

The Shanghai facility’s design is based on NNE’s Bio on demandTM concept, which is highly flexible and based on single-use disposable technology. The facility will allow Boehringer Ingelheim to provide the full cycle of services from DNA to finished product.

The facility features open process architecture and will allow the production of clinical material for pre-clinical, clinical and commercial phases. It is equipped with 2,000l single-use bioreactors with fermentation and purification lines and automated fill/finish capabilities.

The plant’s components include wash and sterilisation facilities, an IPC lab, a seed lab, a cell culture unit, media and buffer preparation units, and purification units. It also features waste control, dispense and storage units.

The facility is designed to allow future changes to be made based on the product mix, as well as future expansion to meet demand. It is also equipped with stainless steel manufacturing lines that can be expanded up to 5,000l.

Contractors involved in the project

Pharmaceutical engineering company NNE carried out feasibility studies and developed the conceptual design for the facility. Multi-disciplinary construction consultancy Archetype Group served as project management assistant, while the Global Shanghai Office was involved in the negotiation and documentation process.