Stelis BioSource™, a division of Stelis Biopharma, is expanding its biologics manufacturing facility located in Bangalore, India.

Expansion is a part of the company’s extended investment programme, under which it already invested more than $100m in its Bangalore facilities.

The facility expansion is the manifestation of strong market demand and opportunities to establish an infrastructure for delivering economic outsourced biologics capabilities.

The investment programme will create a global platform for biologics, vaccines, and pharmaceutical drug products.

Stelis BioSource’s biologics manufacturing facility expansion details

Stelis BioSource’s 200,000ft2 state-of-the-art, integrated commercial biopharma manufacturing facility features microbial and mammalian facilities for cGMP manufacturing. The expansion will equip the mammalian facility with two 2,000l single-use bioreactor trains for CGMP manufacturing of mammalian drug substance.

Single-use technology reduces footprint, costs and time, enabling flexible and efficient manufacturing.

The facility incorporates 50l, 200l and 2,000l production line, fermentation capability, including handling batch, fed-batch and perfusion fermentation process, as well as dedicated pre-culture suites, media and buffer preparation rooms.

The facility features pre and post-viral segregation, filtration and single-use flow path- chromatography systems and controlled freeze and thaw system.

Details of the existing Stelis’ biologics manufacturing facility

Well-connected with the international airport of Bangalore, the manufacturing facility incorporates drug substance (DS) and drug product (DP) manufacturing, fill-finish and packaging capabilities, catering to the customers’ requirements including early-stage development, clinical trial material generation, process validation and commercial manufacturing.

The facility comprises dedicated suites for microbial and mammalian DS and develops simple and complex recombinant biotherapeutics from the cell culture systems. It complies with global industrial guidelines, including the US Food and Drug Administration (FDA), European Medicines Agency (EMA) and World Health Organisation (WHO) standards.

Microbial DS suite and DP facility details

The microbial DS suite is complete with a development line of 50l, 300l and 1,000l conventional SS fermenters assisted by corresponding capabilities for downstream processing utilising single-use technology. It has a dedicated area for pre-culture, conjugation, bulk filtration and lyophilisation, as well as dedicated autoclaves for sterilisation and decontamination.

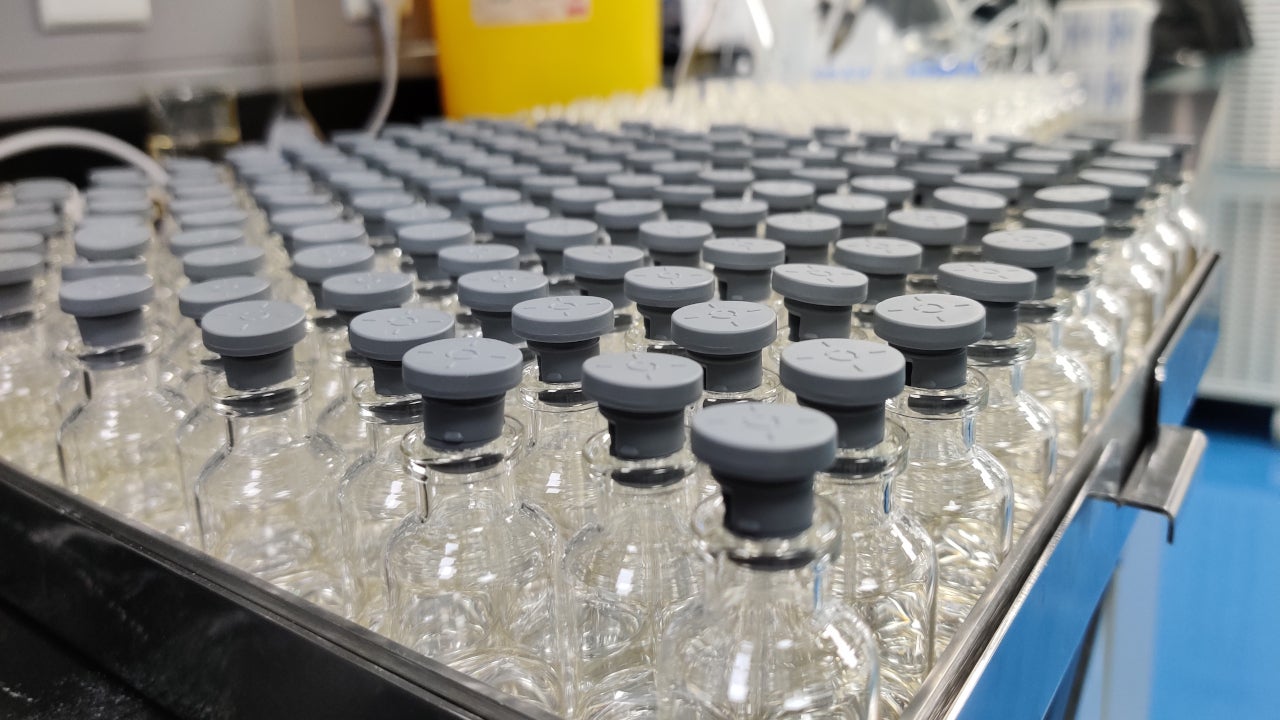

Stelis‘ DP facility uses isolator-based filling lines for improved bioburden protection for the formulation and fill-finish in all injectable formats.

DP facility is supported by completely automatic packaging and assembly lines, designed to provide integrated CDMO facilities to pharmaceutical and biopharmaceutical companies.

Other capabilities of the manufacturing facility

The plant has a fully-integrated automatic packaging line with a labeller, syringe assembling systems, and blistering and cartoning machines.

Fully configured to treat products that require lyophilization, the site uses both conventional and single-use systems to support multi-product cGMP development and to encourage scalable project solutions in line with customer requirements.

It is capable of converting drug substances into stable formulations as well as fill-finish in all injectable formats, including prefilled syringes (PFS), cartridges and vials. All filling lines incorporate insulators to ensure consistent aseptic conditions throughout filling.

It is also equipped with a dedicated warehouse with cold chain management for DS and DPs and provides analytical microbiological quality control testing and validation services.

Marketing commentary on Stelis Biopharma

Founded in 2013, Stelis Biopharma is a vertically-integrated biopharmaceutical company based in Bangalore. It is dedicated to developing and producing high-quality, affordable biotherapeutics.

It has a newly enlarged 30,000ft2 research and development site, based in Bangalore.

The principal shareholders of Stelis Biopharma are Strides Pharma and Tenshi Life Sciences, both based in Bangalore, India, as well as GMS Holdings in Amman, Jordan.

Stelis is committed to reducing the biologics cost and aims to develop the research and development site further. The company continues to assess more developments in its skills and abilities, including those motivated by the emerging Covid-19 pandemic, to satisfy consumer demands.