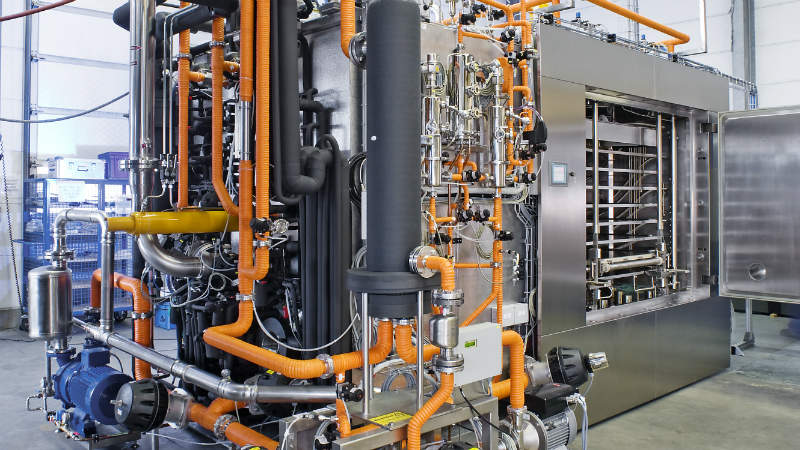

HOF Freeze-Drying Systems

HOF freeze drying systems are tailored individually and precisely to the task at hand and to the specific production requirements.

For systems that are required for research or for product and process development, the company guarantees that the respective process parameters are fully transferable to the production systems, which ensures reliable production.

Each system is also ideally adapted to the structural environment on site.

Vial and bulk systems

HOF specialises in providing individual solutions. That is why freeze drying systems are tailored individually and precisely to the task at hand and to the specific production requirements.

This allows the company to adapt each system to the structural conditions on site. In this area, HOF offers a wide range of freeze-drying systems, with regard to system size, model variants and optional equipment.

Its portfolio ranges from small pilot systems with a 2.5 m2 footprint to systems with a 75 m2 footprint.

Laboratory systems

The high-quality customised laboratory systems from HOF are used in many renowned companies and scientific facilities for research and product and process development purposes.

Highly efficient product results

HOF offers modern systems in compact or split designs. Control, visualisation and technical operation correspond to that of a production system.

Transferring the determined process parameters to a production system is made easier and forms the foundation for reliable production.

Each HOF laboratory systems consists of a fully functioning basic unit. Individual equipment variants for customised solutions are also available, providing the required flexibility for the task at hand.

Specialist individual solutions

HOF is the specialist for individual solutions. That is why freeze drying systems are tailored individually and precisely to the task at hand and to the specific production requirements. This allows the company to ideally adapt each system to the structural conditions on site. In this area, HOF offers a wider range of freeze drying systems, with regard to system size, model variants and optional equipment. The portfolio ranges from small pilot systems with a footprint from 2.5 m2 to systems with a footprint of 75 m2.

The following equipment variants are available:

- Vertical design

- Horizontal design

- Modular technical units which can be installed according to the building situation

- Door concepts (single door, double doors, slot door especially for automatic loading and unloading systems, and slot door integrated into swivel doors)

- The systems can be equipped with different cleaning and sterilising units for aseptic processing areas and with systems for decontamination of the system periphery

- System design for drying products with organic solvents

- Systems for process monitoring and process analysis

- Refrigeration systems (Two-stage refrigeration sets with synthetic refrigerants, cascade refrigeration sets with natural refrigerants, LN2 refrigeration via heat exchangers for the installation areas and the ice condenser, and LN2 refrigeration as direct evaporation for the ice condenser)

For the vacuum systems, HOF offers different variants for different requirements such as:

- Oil sealed rotary vane pumps with or without Roots-type blower

- Glandless pumps with Roots-type blower

- Screw compressor with or with or without Roots-type blower

- Upstream or downstream exhaust gas filtration

As a specialist for individual solutions, HOF can also supply systems for different requirements in bulk production:

- Systems with fixed shelves for loading with trays

- Systems with hydraulically height-adjustable shelves for easier tray handling

- Systems with tilting shelves for cascade filling, with the shelves designed as product pans. The clean-in-place (CIP) / sterilise-in-place (SIP) process can be used here to reload the system with products without opening the chamber door.

Different systems are available for unloading. These are selected according to individual requirements. The same options are available for vial and bulk production systems.