Construction of a drug manufacturing facility for the University of Tennessee Health Science Centre in Memphis, Tennessee, is expected to begin in September 2015. The facility will be known as the Plough Centre for Sterile Drug Delivery Systems.

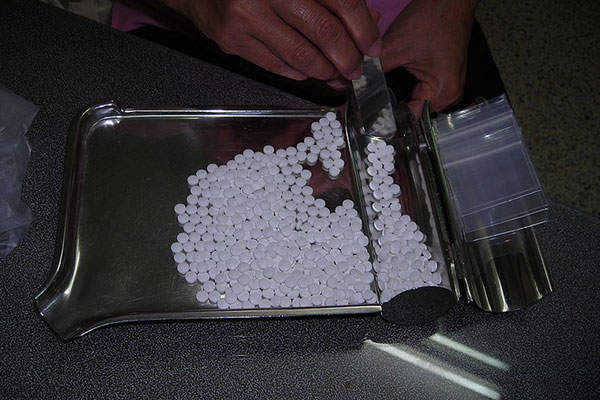

The facility will house pre-manufactured cleanroom pods for the manufacture and filling of clinical trial drugs. It will provide aseptic formulation and clinical trial drug compounding services on a contractual basis for the private sector.

It will be built in compliance with current good manufacturing practices (cGMP) to produce small-batch drugs in injectable and semi-solid dosage forms for pre-clinical Phase I and II clinical trials.

Location of the Plough Centre for Sterile Drug Delivery Systems

The facility will be built by replacing the 32,000ft² warehouse on South Dudley Street, which was bought from Dudley Properties for $750,000 in June 2011. The University of Tennessee filed a $3.7m permit application for the project with the Shelby County Department of Construction Code Enforcement in July 2015.

Details of the sterile drug delivery systems facility in Memphis

The sterile drug delivery systems facility will have a 32,000ft² total floor space, 17,200ft² of which will be given to pre-fabricated sterile pods. It will also include three 800ft² pre-fabricated pods to serve as sterile environments for aseptic pharmaceutical manufacturing.

Pre-fabricated pods will include temperature-controlled and smaller spaces to give control over sterilisation while preparing, compounding and filling pharmaceuticals at a small scale. A total of 10,000ft² of floor space will support labs, offices and training facilities.

The facility will manufacture orphan drugs developed to treat specific and rare diseases, as well as innovative drug delivery systems. It will provide training to students and professionals from the pharmaceutical industry, as well as government regulatory agencies in production.

Construction of the Plough Centre for Sterile Drug Delivery Systems

The two blocks in operation are dedicated to the manufacturing of cephalosporins and general injectables.

Construction of the facility is expected to begin in September 2015 and is intended to be complete within 24 months. It will include renovating the old warehouse, refurbishing the building’s interior and updating its exterior.

Contractors involved in the project

In March 2015, G-CON Manufacturing Sales Engineering was contracted to build a multi-pod ISO Class 7 formulation and filling suite for the facility. The project team includes brg3s Architects, ETFC Architects, DPS Consulting and DPS Engineering.

DPS Consulting will provide pharmaceutical consulting and guidance, while DPS Engineering will provide process architecture and design for the pods.

Financing for the project

The facility will be built with an estimated investment of $16m. Plough Foundation has contributed $4.5m towards its construction.