Germany-based contract development and manufacturing organisation (CDMO) Vetter has started building a production facility at Schuetzenstrasse, Ravensburg.

The company broke ground for the facility on 22 March 2016 in a ceremony attended by Peter Soelkner, Oliver Albercht, Harald Bader, Thomas Ruebekeil, Udo J Vetter, Dr Daniel Rapp, Thomas Otto, Gunther Strothe, Wolfgang Kerkhoff and Christian Schmid.

The $79m project forms part of the company’s $300m investment strategy for the overall modernisation, expansion and rebuilding of its manufacturing sites in Germany.

The facility is expected to be completed by the first quarter of 2018 and will become fully operational in early 2019.

Details of Vetter’s production facility in Ravensburg

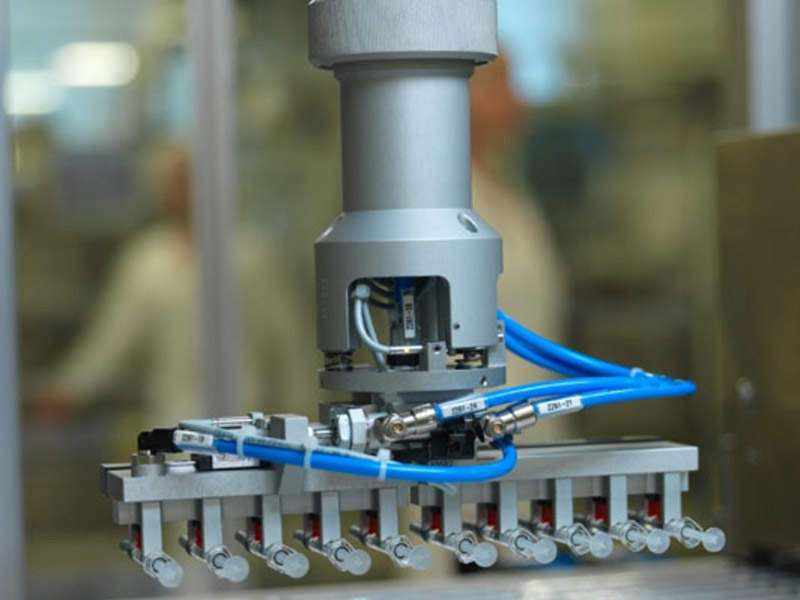

The production facility will be a seven-storey building occupying an 86,000ft² area. It will include a cleanroom equipped with supportive production systems, as well as technologies for filling bulk syringes and sensitive drugs, including biologics and ophthalmic products.

The syringes prepared in bulk will have several customisable options suitable to the substance and primary packaging material components. Further customisation is allowed in silicone levels and the entire process is flexible.

The cleanroom will be designed to achieve the sterility assurance level (SAL) to meet the standards required by regulatory authorities. It will employ an improved restricted access barrier system (RABS) concept, which combines the advantages of isolator for high-level sterility and RABS technology offering greater flexibility and higher capacity utilisation.

The cleanroom’s advanced technology allows the facility to achieve high-level sterility and capacity utilisation of filling lines while running multiple products. Its fully automated decontamination process will involve a three-hour cycle using hydrogen peroxide (H₂O₂).

The facility will also comprise an on-site central material preparation area, office space for the production staff, and a staff canteen with a roof garden.

Marketing commentary on Vetter

Vetter is a contract development and manufacturing organisation (CDMO) that supports its clients by guiding their products through development, regulatory approvals, launch and lifecycle management. The company offers fill and finish contract manufacturing services for prefilled syringe systems, cartridges and vials.

Based in Ravensburg, Germany, Vetter has production facilities in Germany and the US, as well as offices in Singapore and Japan. It currently employs around 3,600 people in total.

The company provides state-of-the-art manufacturing from early clinical development to commercial filling and final packaging of the parenteral drugs, with 35 years of experience in producing a range of complex compounds, including monoclonal antibodies, peptides and interferons.