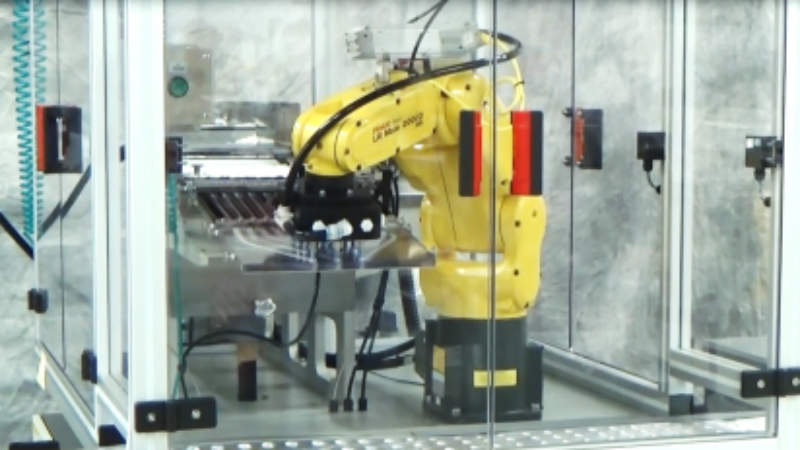

Bulk Product Elevator

Aylward's Bulk Product Elevator safely maintains products levels of up to one million an hour. It has a movable frame on castors with a break.

Aylward manufactures tablet counting and blister-feeding equipment, bulk elevators and customised packaging automation solutions.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Aylward manufactures solid dose packaging solutions, including tablet counting and blister-feeding equipment, bulk elevators and customised packaging automation solutions.

For more than 40 years, Aylward has developed innovative technologies and provided engineering and manufacturing capabilities for the pharmaceutical, nutraceutical, medical, animal health and packaging industries.

The company provides custom-made solutions for products that are fragile or odd-shaped, which are packaged in blister packs, bottles, pouches or cartons.

With decades of experience, Aylward specialises in handling, counting and blistering tablets, capsules and liquigels.

The company combines its innovative and customisable solutions with a flexible engineering culture to meet industry challenges.

Aylward’s patented 100% accurate tablet counting technology precisely counts and packages pharmaceuticals into bottles, reaching speeds of up to 400 bottles per minute (BPM).

The tablet counter has an Allen Bradley control system, a small footprint, tool-less changeover, and very few product contact parts.

Aylward is a leading manufacturer of blister-feed systems for blister thermoforming machines. The units reliably place tablets into blisters at rates of up to 50 cycles per minute (CPM).

The company’s dedicated feed systems have been installed worldwide, addressing complex and challenging applications.

Aylward’s capabilities include:

Aylward provides automated solutions to package a wide variety of pharmaceuticals into blisters, bottles, pouches, or cartons.

The company works closely with other suppliers and easily integrates its equipment onto clients’ pre-existing packaging lines.

Aylward aims to enhance its clients’ packaging process and product quality by providing a practical automated solution with its high-quality service and support.

Since inventing the first dedicated blister feed system in 1977, Aylward is often selected due to its unique abilities to handle difficult and speciality projects. The company provides dedicated service and support throughout the service life of pharmaceutical equipment.

Aylward's Bulk Product Elevator safely maintains products levels of up to one million an hour. It has a movable frame on castors with a break.

Aylward's 9000 SERIES Bottle Filling Machine is easy-to-use, fast and accurate, offering precise fill control and built-in product containment.

Aylward has announced that it will be showcasing its solid dose packaging solutions at this year’s Pack Expo Las Vegas.

Aylward has announced it will be attending Pack Expo International in Chicago, US.

Aylward is a custom engineering-driven facility, producing speciality one-off packaging equipment to meet requirements set forth by the customer.

The newest innovation to Aylward’s blister feed system offerings, The Cube is all servo motor driven and covers a blister format size of up to 600mm in web direction.

With three models to choose from, the XYZ Feed System is one of the most recognised dedicated feed systems on the market.

The Compact Blister Feed System has five models to choose from and is intended for small-to-medium output machines.

Aylward’s distinctive method of counting allows its machines to repeatedly control tablets like never before.

The newest innovation to Aylward’s blister feed system offerings, The Cube is all servo motor driven and covers a blister format size of up to 600mm in web direction.