Powder Rheology

Conglomerations of fine particle solids, along with the gaseous space between them and to a lesser extent the encompassed moisture, make up what is simply known as “powder”.

Rheo Engineering offers material handling products and turnkey process systems for pharmaceutical applications to help clients design processes and systems that allow materials to flow from one point of the process to the next.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Rheo Engineering offers material handling products and turnkey process systems for pharmaceutical applications to help clients design processes and systems that allow materials to flow from one point of the process to the next.

Material handling should be considered in the early stages when designing and developing any process. Rheo examines how substances move within an operation, creating systems that ensure optimised process flow.

The company works with clients during the entire process, from the initial concept and feasibility review to the delivery and start-up of a turnkey system.

Rheo’s solution-oriented team is focused on understanding where our systems fit into the overall manufacturing process. We understand process flow and the critical factors considered in the design.

Factors include safety, product integrity and optimal utilization of fundamental manufacturing assets, as well as throughput and cost of ownership.

We have an experienced team of project managers, engineers, fabricators and mechanics that enable us to control project schedule and equipment quality.

Our technologies are developed in-house and when combined with an effective original equipment manufacturer (OEM) network, we can offer plant-wide solutions and integrated process systems.

Understanding key elements of clients’ process via on-site assessments involves reviewing plant material handling, batch records, application details, and material characteristics; as well as creating process diagrams and interviewing key stakeholders.

Determining how we can work for each client includes conducting operations assessment reports, determining critical design considerations, testing with mock-ups or demo equipment, utilizing the Rheo Testing Center, providing sample drawings, managing product configurations and developing process flow diagrams.

Our attention to detail shows throughout the process. We focus on project management, custom design engineering, mechanical design integration and controls integration. Full vertical integration allows control of quality and timeline.

Rheo conducts factory acceptance tests and system start-ups, providing installation supervision and operator training while our after-sales support ensures complete client satisfaction.

Rheo has its clients covered from concept to final project delivery, installation and start-up.

Our experienced team, a strong network of OEM partners, and our hands-on approach to applying technology in our Testing Center equip us to deliver comprehensive handling systems to achieve our client’s complex process requirements.

Engineering and automation teams design, source and fabricate complete systems by integrating Rheo and OEM equipment. Our in-house manufacturing allows us to produce our products, as well as make any modifications to ensure reliable integration of all process equipment.

Our team understands the three core challenges of material handling: containment, safety and productivity, designing our systems keeping these in mind.

Running live tests is a critical part of process design and system performance verification. The Rheo Testing Center is a full-service pharmaceutical room where we can run a wide variety of processes for our clients to evaluate process feasibility and verify the performance of process design.

Our lab allows for proof of concept, powder flow testing, process validation, system mock-ups, Standardized Measurement of Equipment Particulate Airborne Concentration (SMEPAC) containment performance testing, clean-in-place (CIP) testing, process analytical technology (PAT) instrumentation calibration, and many other services.

Rheo has several products available for demonstration purposes and testing with the integration into large systems, available to test at client facilities.

We can conduct industrial hygiene (IH) testing according to International Society for Pharmaceutical Engineering (ISPE) SMEPAC guidelines or clients’ industrial hygienists can complete testing at Rheo facilities.

Complete client satisfaction is our number one priority. At Rheo, we recognize that our future relies on satisfied clients that have realized success in their project because of our efforts. This is evident in the dedicated level of service woven into the fabric of our company.

During each step of the project, our team maintains a focus on the result. This focus drives the decisions and communications from the early assessments phase to the post-start-up phase. Timeliness is critical, and we commit to a prompt and responsive customer service department.

Conglomerations of fine particle solids, along with the gaseous space between them and to a lesser extent the encompassed moisture, make up what is simply known as “powder”.

Rheo Engineering has introduced a new division of our company, Rheo Flexibles. Rheo Flexibles provides a full range of single-use products, all designed and manufactured at our facility in Peoria, Illinois.

Rheo introduces the latest Vacuum Lift design. The Vacuum Lift is the simplest and most effective material handling solution for manipulating containers effortlessly in three-dimensional space.

Rheo has expanded our product offerings to include Bins and Bin Blenders.

The Rheo Material Transfer Station [MTS] offers cutting edge technology to allow fast and contained transfer of powders into process equipment.

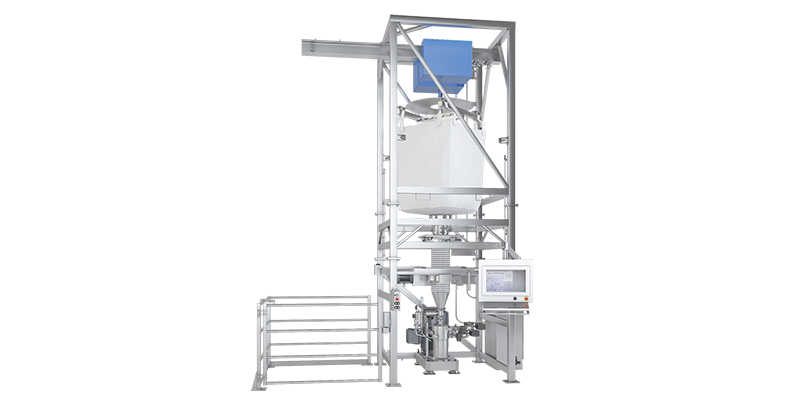

Bulk Bags offer supply chain cost reductions in the life sciences industry, however, they also introduce significant material handling challenges within the manufacturing process.

Bulk bags offer several advantages to a facility's bulk powder handling operations.

For the transfer and mixing of bulk solids to liquids, Rheo Engineering has developed, created, and tested an ideal solution.

Rheo designed and built an integrated system for transferring solids bulk bags into process vessels through a high shear induction mixer.

Rheo designed and fabricated an integrated system to carry out the milling of salts (drum and bag stock) as they were charged to a buffer preparation tank.

This project started at Rheo’s testing center in Peoria to develop a proven design; mocked up and tested with a number of client’s powders.

Rheo designed and fabricated an integrated system for transferring a variety of highly potent materials into process vessels through a high shear mixer.

Rheo Engineering recently partnered with Visval to bring their revolutionary SoliValve® to North America. We integrate this technology into our material handling systems.

EHS Solutions introduces a new name for our company – Rheo Engineering. Rheo, a Greek prefix meaning “flow,” truly reflects what we’re best at: designing and building engineering systems for material flow.

Running live tests is a critical part of process design and system performance verification.

EHS Solutions has shown growth throughout the history of the company

The Rheo Material Transfer Station [MTS], is designed to help operators transfer material out of drums using a small footprint workstation.

The Rheo Drum Conditioner provides a safe and reliable means of conditioning hardened product within raw material containers.

The patented Rheo Drum Tipper is designed to help operators safely transfer materials out of drums while providing access to the drum contents.

The Rheo Bulk Bag Unloading Station is a GMP system that is designed to work with a wide range of containers and processes.

Bins provide a unique opportunity to optimize process flow for many operations. The key advantages of using bin blending technologies are modularity, quality, and increased output.

Rheo Flexibles is a division of Rheo Engineering that provides single-use products.