REGENXBIO built a research and development (R&D) facility, which it calls the Manufacturing Innovation Center, in Montgomery County in Rockville, Maryland, US.

The facility will provide the company with complete control over the entire gene therapy manufacturing process in Montgomery County. The project was announced in November 2018 and the facility was opened in June 2022.

Until December 2021, the company had allocated more than $100m towards the development of its headquarters in Rockville, which includes more than $65m invested in the Manufacturing Innovation Center located within the headquarters.

REGENXBIO’s research and development facility location

The R&D facility is located in the Alexandria Life Science and Translational Research Center at 9800 Medical Center Drive in Rockville.

The campus at 9800 Medical Center Drive currently has four buildings encompassing 282,000 rentable square feet (rsf). It exceeded approximately 460,000rsf after the completion of the new facility.

REGENXBIO entered a 15-year lease agreement with Alexandria Real Estate Equities for 132,487rsf in November 2018. It is situated close to government and regulatory authority institutions such as the National Institutes of Health and the US Food and Drug Administration.

Relocating its headquarters enables REGENXBIO to recruit a skilled workforce, form collaborations, and provide growth opportunities.

Details of REGENXBIO’s new R&D facility in Maryland

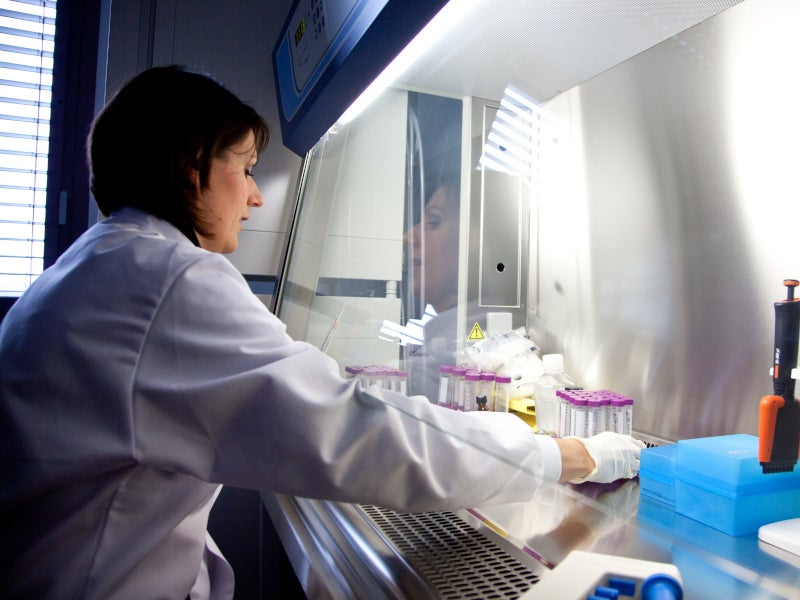

The state-of-the-art current good manufacturing practice (GMP) facility is a five-storey building. Its interior construction was carried out in two phases, encompassing approximately 20,000ft2 of clean room space.

The fit-out during the first phase covered the first, third, and fourth floors, involving the construction of labs, offices, conference rooms, training spaces, and support areas, including mechanical, electrical, and plumbing rooms on the first floor. The first floor encompasses approximately 13,897rsf while third and fourth floors span approximately 39,530rsf each.

The design team placed the clean room suite on the uppermost (fifth) floor, elevated the height of the fifth floor, and incorporated the most extensive penthouse permissible by the municipality, ensuring it did not qualify as an additional building floor and thereby avoiding an increase in the overall building height.

The second phase focused on the fit-out of the fifth floor, covering approximately 39,530rsf and penthouse equipment. This included the development of manufacturing and production GMP clean rooms, support spaces, quality control labs, and additional office spaces. Additionally, the second phase incorporated GMP warehouse space on the first floor.

The facility has two separate bulk drug ingredient manufacturing suites and a final drug product suite. It is built to satisfy global clinical and commercial regulatory requirements.

The building has been permitted for use as an office, R&D lab, training area, as well as a biotechnology laboratory. The facility enabled the company to improve the manufacturing of adeno-associated virus (AAV) vectors, utilising the company’s proprietary NAV technology platform, reaching capacities of up to 2,000 litres.

The facility adopted the suspension cell culture technique, NAVXpress platform, and demonstrated its capacity to enhance both product purity and yield.

It is designed to achieve Leadership in Energy and Environmental Design Silver certification and features metal framed walls, a double-glazed glass roof, and single-glazed skylights. LED lighting is used in public, parking, and common areas.

Financing

Maryland Commerce granted a $700,000 conditional loan via the Advantage Maryland programme for the project. REGENXBIO was also eligible to receive the Partnership for Workforce Quality grant, aiding in meeting training requirements.

Additionally, Montgomery County provided a conditional grant of $100,000 and supported the permit approvals process. The Montgomery County Economic Development assisted in coordinating with partners and facilitating the project.

Technology used at the new facility

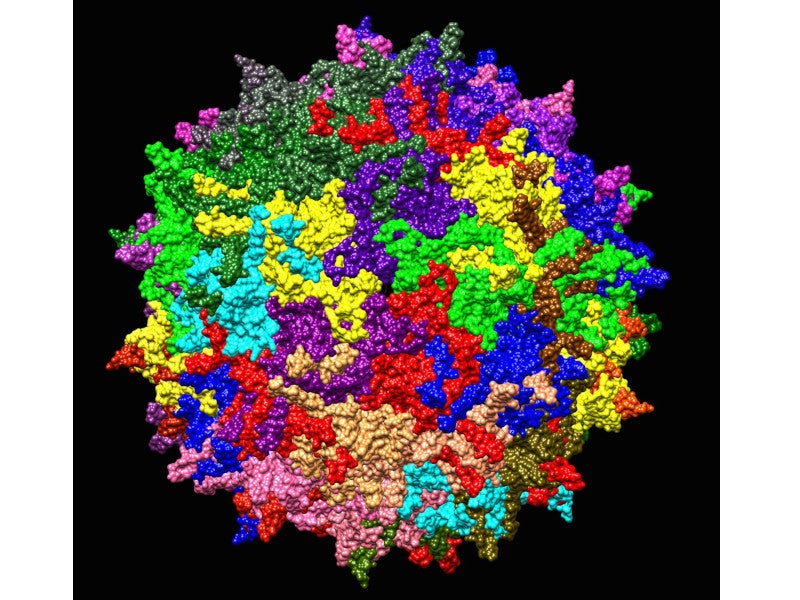

REGENXBIO’s gene therapy delivery platform, NAV technology, uses viral vectors for the delivery of genes into cells, which corrects genetic malfunctioning and deficiency by producing therapeutic proteins in the body.

The platform holds exclusive rights to AAV7, AAV8, AAV9, AAVrh10, as well as more than 100 new AAV vectors, which are used to develop a wide range of gene therapy candidates in various therapeutic areas.

The NAV vectors, derived from natural sources, reduce the risk of triggering an immune response compared to previous-generation AAV vectors. The NAV platform streamlines the manufacturing process compared to previous AAV vector versions.

Contractors involved

EwingCole, an architecture and engineering company based in the US, was responsible for providing design and engineering services for the project, including automation, controls, electrical, power, energy, sustainability, fire, life safety, mechanical, lighting, plumbing, and piping.

Marketing commentary on REGENXBIO

REGENXBIO is a clinical-stage biotechnology company focused on the development of a pipeline of gene therapy candidates for a wide range of diseases.

The company is currently working on more than 20 programmes with multiple partners and licensees of the NAV technology.

By 2025, REGENXBIO plans to advance five AAV Therapeutics from its internal pipeline and licensed projects into either pivotal-stage trials or commercial products, as part of its ‘5x’25’ strategy.