Blending Systems

METO Systems provides lab-scale blenders, container blending solutions, and drum blenders suitable for blending various types of ingredients.

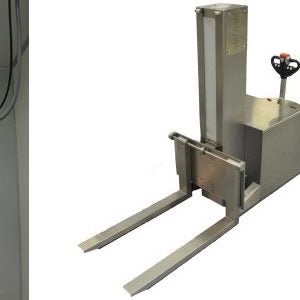

Lab-Scale Blenders

METO Systems’ stainless-steel lab-scale blenders mimic the full-size blender but are sized for containers measuring up to 5ft. The unit has a fixed height and can blend round or square containers. The base is fitted with full locking swivel casters and floor levelling locks to allow safe blending.

Our blenders prevent product exposure, cross-contamination and product loss, making them ideal for high-potency materials. They also minimise space requirements in your facility because they can blend, lift and position right onto a lift column. This allows the product to be blended and discharged directly to the next stage of the process without the need for additional handling. Plus, our fail-safe lift mechanisms hold the platform in place even in the event of a power loss.

METO System’s laboratory blenders, with minimum space requirements, can blend, lift and position right onto the column to ensure not only that the product gets blended consistently, but that it is also quickly discharged for further processes. Its failsafe lift mechanism and the full locking swivel casters and floor levelling locks ensure safe bending and that the system is kept in place on the platform in the event of power loss.

Container Blending

METO Systems’ stainless-steel bin blenders prevent product exposure, cross-contamination and product loss, making them ideal for high-potency materials. They also minimise space requirements in your facility because they can blend, lift and position right onto a lift column. This allows the product to be blended and discharged directly to the next stage of the process without the need for additional handling. Plus, our fail-safe lift mechanisms hold the platform in place even in the event of a power loss.

The advantage can be leveraged even further by blending, lifting and positioning on a lift column. The product is blended and discharged directly to the next stage of processing without the need for further handling. The same can be done using drums and other types of product containers.

Drum Blenders

Drum tumbling is a common way to keep ingredients in liquid suspension and to break up powder clumps prior to discharge. It’s also a standard way to simply mix ingredients.

METO Systems’ sanitary drum tumblers work for all three activities, but they differ from more common drum rollers in that they rotate the drum end over end instead of spinning about the centre axis. This ensures a more robust agitation action inside the drum and removes the need to position it on its side.