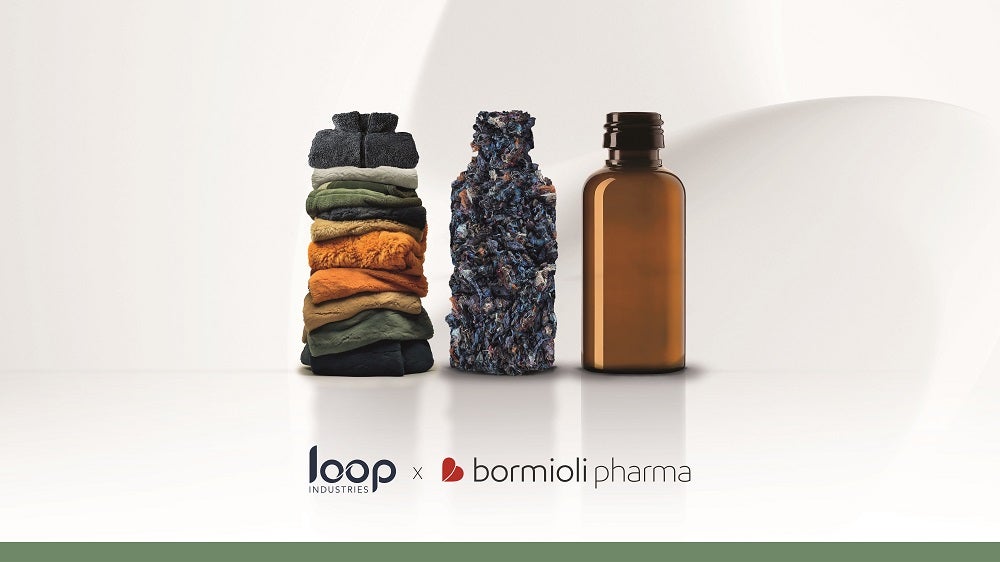

Bormioli Pharma and Loop Industries Unveil an Innovative Pharmaceutical Packaging Bottle Manufactured with 100% Recycled Virgin Quality Loop PET Resin at Pharmapack 2024

Bormioli Pharma, an international leader in pharmaceutical packaging and medical devices, and Loop Industries (Nasdaq: LOOP), a clean technology company whose mission is to accelerate a circular plastics economy by manufacturing 100% recycled polyethylene terephthalate (PET) plastic and polyester fibre, today announced that an innovative pharmaceutical packaging bottle manufactured with 100% recycled virgin quality Loop™ PET resin will be unveiled within the Bormioli booth at Pharmapack Europe 2024.

The pharmaceutical industry is increasingly recognising the importance of adopting sustainable practices and materials to reduce its environmental impact. Loop’s 100% recycled virgin quality PET can help support pharmaceutical companies with a sustainable packaging alternative and address the growing demand for environmentally responsible choices in the industry. The Infinite Loop™ technology upcycles the lowest quality PET and polyester fiber waste into 100% recycled virgin quality Loop™ PET resin.

A recent test, executed by a worldwide leader in laboratory testing, confirms that Loop™ PET resin has successfully met the strict standards and requirements outlined by the EU Pharmacopoeia (Ph.Eur. 3.1.15, Polyethylene Terephthalate for Containers for Preparations not for Parenteral Uses) and US Pharmacopoeia (USP <661.1>, Plastic Materials of Construction) and is compliant for use in packaging applications in the pharmaceutical industry. Loop™ PET resin helps create circularity for low value waste while reducing greenhouse gas emissions and can save up to 360,000 tonnes of CO2 per year compared to virgin PET made from fossil fuels.*

Bormioli Pharma and Loop Industries aim to introduce market-ready solutions for the global pharmaceutical industry and the two companies began to collaborate over a year ago in order to achieve this goal. Bormioli Pharma tested Loop™ PET resin in its packaging, commissioning to independent third parties’ additional analysis to verify extractables levels with different solutions, also taking in consideration the worst-case scenario. The results of these tests are unprecedented for a recycled plastic product, as the bottles produced with Loop™ PET resin do not release any substance deemed of toxicological relevance**, setting a new benchmark within the pharmaceutical industry.

Bormioli Pharma’s EcoPositive offering, gathering low-impact packaging solutions, currently constitutes 50% of the Company’s standard catalogue, contributing to position itself among the players with the broadest sustainable offerings on the international market.

“Through this collaboration with Loop we’re strengthening our role as a solid, quality and reliable partner for the pharmaceutical industry,” stated Andrea Lodetti, CEO of Bormioli Pharma. “Loop Industries shares our values and commitment, and together we made available a new pharma-grade sustainable solution, showing even greater safety standards than traditional ones.”

Daniel Solomita, Founder and CEO of Loop Industries, commented: “Through our collaboration with Bormioli Pharma, we have developed an innovative pharmaceutical packaging solution manufactured from 100% recycled virgin quality Loop PET resin. This high-quality packaging alternative raises the bar for responsible solutions and helps set a new standard for sustainable packaging in the pharmaceutical industry.”

* Source: Life Cycle Assessment of Loop GEN II Infinite Loop™ France done by Franklin Associates, a division of ERG, compares kg for kg Loop PET vs. Virgin PET. CO2 savings are based on a 70,000 tonne Loop facility and are compared to the production of virgin PET made from fossil fuels and the avoided incineration of waste used as a feedstock.

** Results from an extractables study conducted by an independent, external lab and performed on bottles manufactured with Loop™ PET resin using different simulating solutions.