Continuous Wet granulation and Fluid-Bed Drying

Continuous wet granulation and drying have long been a hot topic in pharmaceutical research and development (R&D) and industry.

LB Bohle develops and manufactures customised single machines and complete assembly lines for pharmaceutical solids production applications.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

LB Bohle develops and manufactures customised single machines and complete assembly lines for pharmaceutical solids production applications.

Our product portfolio comprises all process steps. In addition to weighing, granulation and blending systems, the range also includes milling and sieving systems, film coaters, and containers and lifting systems that are tailored to meet sensitive material handling requirements.

All production steps, from spraying to drying to blending, must be aligned to achieve high-quality results in the coating process. From laboratory to process machine, LB Bohle’s cutting-edge coaters guarantee high profitability.

Aside from homogeneous coating, the machine series delicately handles tablets. A flat tablet bed in an extensive drug geometry, as well as continuous adjustment of the inclination angles, ensures optimal movement of the cores.

Continuous product movement is enabled through the systematic compulsory guide within the drum, preventing tablet twinning and significantly decreasing losses in solids and coatings. Furthermore, the air system creates advantages in process technology, eliminating the risk of spray drying of the suspension.

Our smaller-scale laboratory blenders and the production-scale blenders PM employ container volumes between one to 12,000 litres.

Our PM systems are not only distinguished by their patented technology with a counter-current process but also maximum flexibility in their application, assuming a blending function and acting as a feeder of process machines.

Aside from the PM range, the series also comprises blenders specifically for third-party containers.

We meet the growing demand for dry granulation applications by offering the BRC 25 and the innovative variable gap dry granulator BRC 100.

The BRC machines allow high production volumes with marginal material loss, which is achieved through fast and precise control of the compaction force with electromechanical spindle drive for the two rollers.

In arrangement with delicate control of the adjustable gap through a screw-feeding system, continuous ribbon properties are guaranteed over a comprehensive product range from less than 1kg to 400kg / h.

Our headquarters are in Ennigerloh, Germany, and have an operating area of approximately 40,000m² and a highly qualified team of 250 specialists.

In LB Bohle R&D department, pharmaceutical experts, mechanical engineers and process and software experts work together with the entire production process carried out in the company‘s service centre.

Spanning an area of more than 600m², the production of batch sizes between 10kg and 30kg is possible. Comprising weighing stations, granulators, fluid-bed technology, container blending, sieving and milling stations and tablet presses, our machines can be used in a modular way or for clinic sample production.

For our company, the ongoing development of processes and machines is an essential part of the business model. More than 45 patents strengthen our position as a technical leader in the industry. State-of-the-art solutions range from ventilation systems to individually shaped coils, which inhibit spray throughout the coating process.

Continuous wet granulation and drying have long been a hot topic in pharmaceutical research and development (R&D) and industry.

Throughout the past years, continuous manufacturing has become an important topic for both pharmaceutical companies and regulatory agencies around the world.

This free whitepaper gives details on LB Bohle's products and services and how they can benefit your operations.

Rapid development and the best results right from the start are the goals of research and development departments in the pharmaceutical industry. This also applies to the tablet coating process.

Tablets are the most important oral dosage form in the pharmaceutical industry. The advantages of tablets are numerous.

Dry granulation, also known as roller compaction, has become a widely used granulation technology in recent years. It has a wide range of applications.

The pharmaceutical production of tablets is practically unthinkable without the use of a sieve or a mill. These are needed whenever active and inactive materials are handled, and tablets or other products are being manufactured.

Perfect handling is critical to optimising your production processes: Whenever raw materials must be supplied, products transported, safely packaged or stored, a wide variety of containers and lifting systems are used.

In the pharmaceutical industry, one term is becoming increasingly important: containment. It describes the process of containing a substance within a defined space, a method that is suitable for protecting operators and the environment in case of high toxicity and product reactivity.

Europe’s leading sustainability rating organisation, EcoVadis, has awarded a Silver medal to LB Bohle, recognising the pharma industry process machinery leader’s latest advances in environmental sustainability.

World-respected builder of advanced systems for pharmaceutical production, LB Bohle, will demonstrate its advanced dry granulation and continuous production capabilities at the upcoming MEDELPHARM Distribution Seminar (MDS) in France.

On 10 June, the leading trade fair ACHEMA starts in Frankfurt am Main. LB Bohle Maschinen und Verfahren cordially invites you to visit our booth - Hall 3.0 Booth A49 / A71.

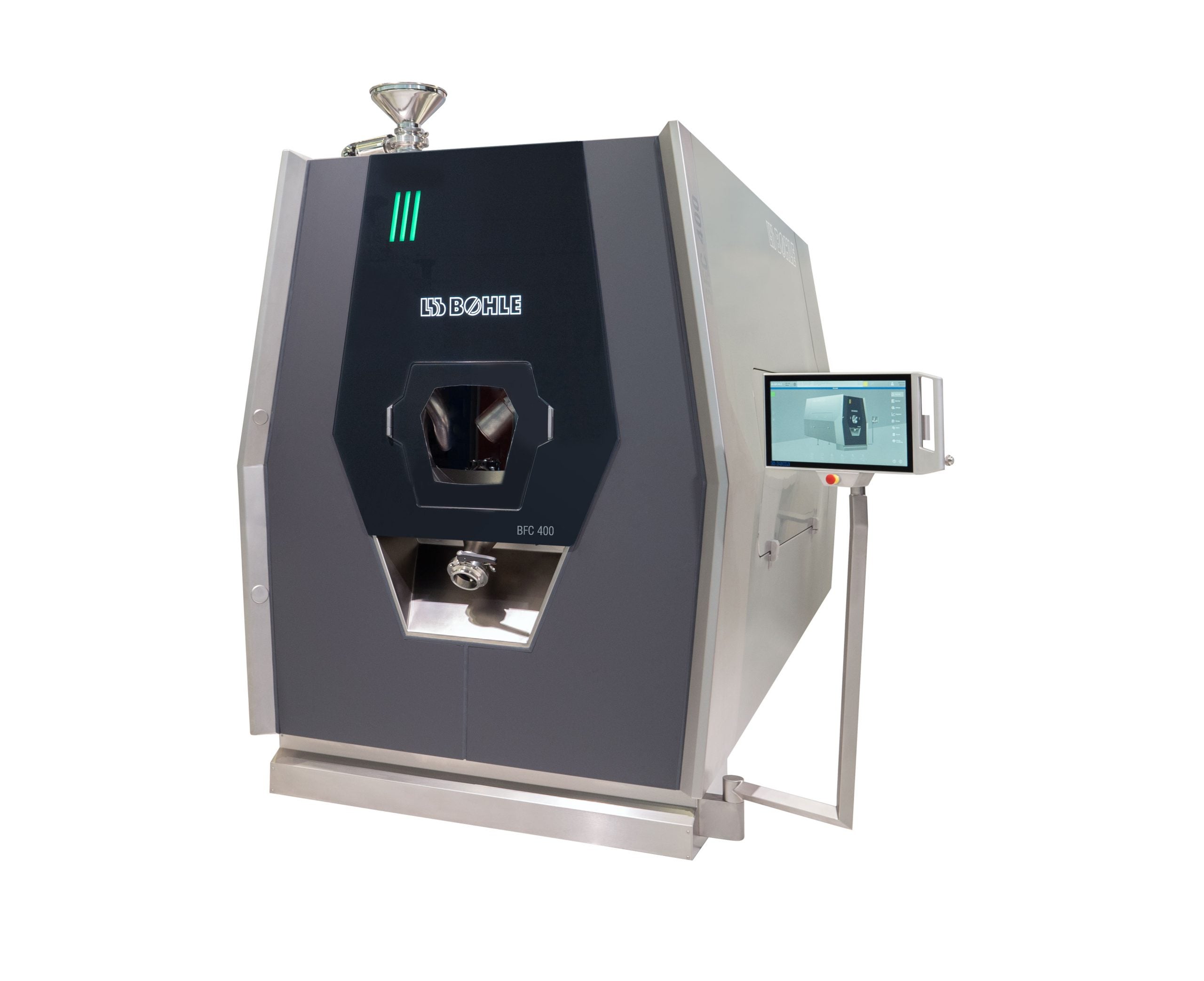

L.B. Bohle once again focuses on new machines and continuous manufacturing at the ACHEMA. After three machines ‒ the BFC 400 tablet coater, the BRC 100 dry granulator and the QbCon® 1, the only truly continuous wet granulator and dryer - were not only presented but also awarded the German Design Award, L.B. Bohle is following up at Achema.

There was great joy at LB Bohle, as the technology company from Ennigerloh has won the German Design Award three times.

State-of-the-art technology 'packed' in a modern way

LB Bohle will return to the prestigious INTERPHEX pharma expo in New York to showcase significant advances in solid-dose manufacturing.

Landing page whets visitors' appetite for the trade fair

Come and meet our team to discuss current projects and find out more about our machines and processes.

Come and visit our team at ACHEMA 2022, in Hall 3.0 at booth A49/A71 to discuss our latest innovations in Containment.

Start of the production of machines for Continuous Manufacturing

Based on continued success, L.B. BOHLE and KORSCH AG have announced the opening of a new facility in Hyderabad, India, which will serve as a competence center to support equipment sales, technical services, and spare parts. An inaugural event is planned in April 2022.

Compact Granulation System Secures Small Footprint, Flexible Application and Smooth Production Processes

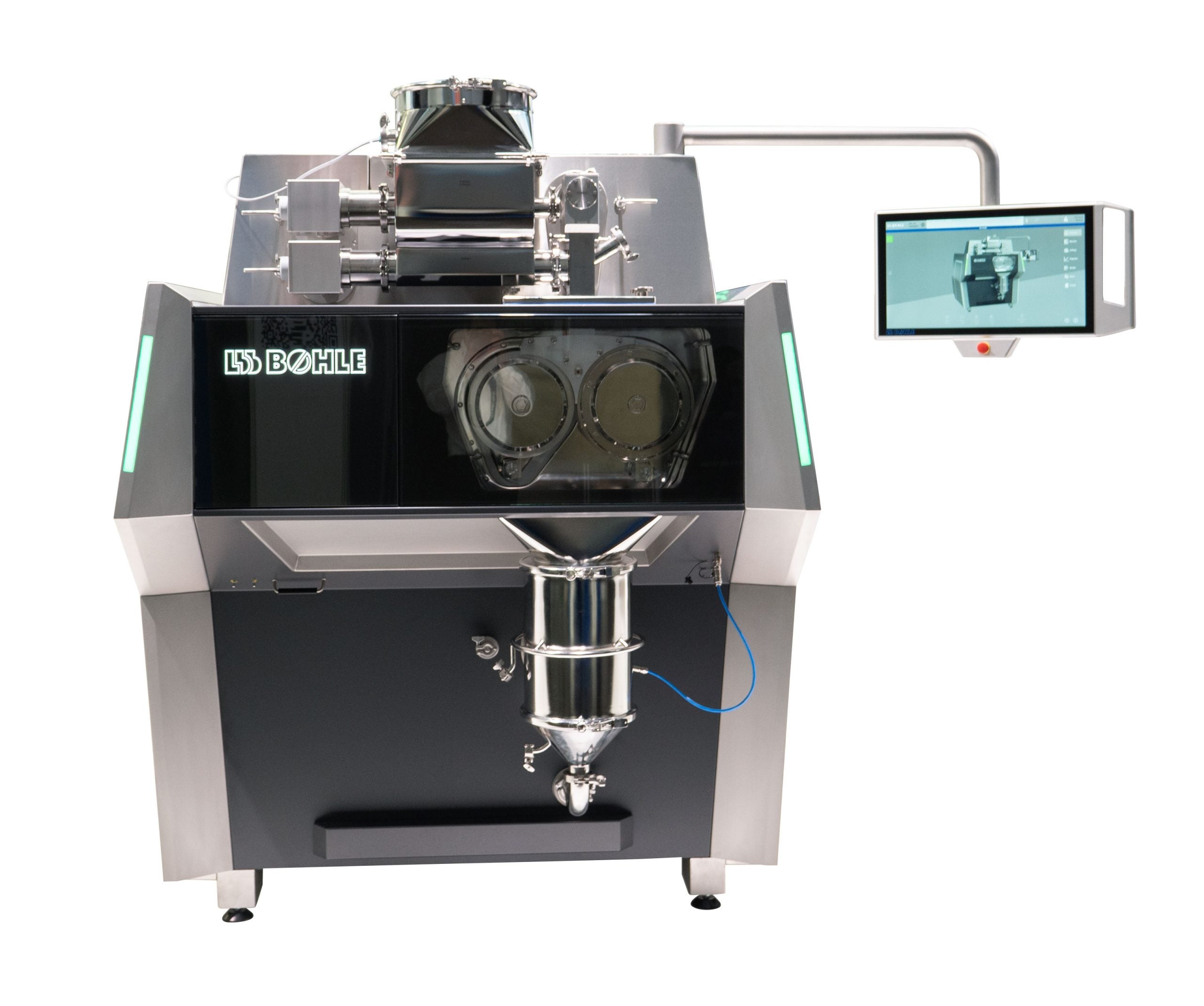

Last month, after close to a year of project time, a German producer of generic products famously accepted the Factory Acceptance Test (FAT) of continuous wet granulator and dryer QbCon® WG.

A British multinational company entrusted LB Bohle with a unique assignment: development of a containment coater specially designed for research and development (R&D) purposes.

LB Bohle now offers a test and development centre for trials and process optimisation in Warminster, Pennsylvania, US.

LB Bohle recently hosted a half-day workshop at its Ennigerloh headquarters in cooperation with Rottendorf Pharma.

Constant and continuous drying must be guaranteed to seamlessly connect to continuous wet granulation.

Due to Covid-19 travel restrictions, LB Bohle uses video conferences in order to organise is daily business.

Leading trade fairs are in fact the place to present new products, and that is what LB Bohle had planned as well: the new QbCon® 1 and first truly continuous dryer BCD were to celebrate their world premieres at Interphex in the USA and Interpack in Düsseldorf.

Granulation is an important process step in the manufacturing of pharmaceutical products. Granules may be used directly as pharmaceuticals or serve as an intermediate product in the manufacturing of tablets or capsules.

For decades, high shear single pot granulation has been a well-established process technology within the pharmaceutical industry.

Granulation continues to grow in importance in the pharmaceutical industry due to the increasing pressures related to cost in the production of solid dosage forms. Granulation aims to form coarser agglomerates from fine powder.

The pharmaceutical production of tablets is practically unthinkable without the use of a sieve or a mill. These are needed whenever active and inactive materials are handled and tablets or other products are being manufactured.

In the pharmaceutical industry, one term is becoming increasingly important: containment.

LB Bohle has been the technological leader for all film coating applications for more than 15 years.

Using a tangential fluid bed system represents state of the art technology in pharmaceutical manufacturing for particle coating, granulation and drying.

The pharmaceutical industry’s demand for continuous processes is increasing because it offers clear advantages such as cost savings, process robustness and no scale-up hurdles.

The Bohle blending systems allow homogeneous blending of dry powder batches with its patented blending elements mounted to the inside of the container lid.

With QbCon® 1, LB Bohle presents a means for solids production in the pharmaceutical industry to combine the three processes of continuous raw material dosing (mixing of excipients and active ingredients), continuous twin-screw moist granulation and continuous drying in one plant including integrated control.

LB Bohle creates customised single machines, as well as whole assembly lines, for pharmaceutical solids production applications.

This video gives an overview of LB Bohle's BRC 25 roller compaction machine.

This video gives an overview of LB Bohle's BFC 5 film coater machine.

This short video illustrates the tablet coating process, giving an inside look at how LB Bohle achieves excellence in tablet coating.