METO Systems to Attend This Year’s INTERPHEX Show: October 19-21, 2021 at Booth #2471

Join Us at The INTERPHEX 2021 Technical Conference, Live and in Person. This year’s event will be held at the Javits Center, 429 11th Ave, New York, NY 10001.

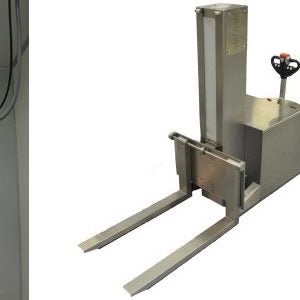

METO Systems designs and manufactures state-of-the-art stainless-steel material handling and processing equipment for a wide range of industrial processing and manufacturing applications. Whether you are looking to upgrade a single piece of equipment for an existing production line, or are developing a new manufacturing process, our engineering staff can provide expert insights and guidance on product and systems selection.

Our dedicated, trained and highly-experienced staff provide continuous on-site support to ensure maximum utilization and smooth functioning of our material handling solutions and other types of equipment. We help our clients to set up (on-site installation), machinery start-up, operation training, and equipment validation testing. METO Systems also provides customization of our products to suit your business demands.

- Unparalleled stainless-steel construction

- Electric, hydraulic or pneumatic drive systems

- Safety-minded operations

- Fail-safe functions

- Engineered to suit your specific needs

- Minimal Maintenance

- Easy to clean design

- Well-equipped to handle replacement products

- Manufactured in the United States

Gain special insight into our many innovative material handling products that service regulated manufacturing industries.

Learn more about our blending systems used throughout industries for blending, lifting, positioning and discharging. We offer a rugged, reliable design that can run 24/7/365 with minimal routine maintenance.

About Our Flagship Drum Conditioners

Drum Conditioners (Massagers), are used to break up packed or solidified material. The METO Systems drum conditioner is applicable in warehouse environments, GMP areas, hazardous locations, or simply anywhere on site with an air supply. The unit applies pressure through horizontal and vertical bars, with the drum, box or bag’s internal liner still tied and the lid still attached. Four, 2.5” air cylinders then generate up to 1600 pounds of crushing force to apply pressure evenly yet through multiple points of contact over the drum surface.

Design and Performance

Manufactured from 304 stainless steel, this unit is fully pneumatic, no hydraulics, and no electrical requirements. It is equipped with a manual turntable to hold the drums, floor locks, two-handed controls for safe operation, and four abrasion-resistant polyurethane wheels to allow for easy maneuverability. Capable of handling bags and boxes ranging from 12” to 22” square base area, and drums ranging from 12” to 22” in diameter.

Give us a call for a project discussion while we are at INTERPHEX.

To pre-schedule a personal project discussion, either call at 201.405.0311 ext. 217 or visit our online calendar.

Customer Service Updates

As a result of COVID-19, we’ve now integrated virtual demos, FATS, and trainings upon request.

For drum conditioners we provide in-house testing of materials or rental of the conditioner unit to client facilities so they can test it in the live production environment.