Product Loss – Bag Independence

A multinational contract development and manufacturing organisation (CDMO) with a $5bn turnover develops and manufactures pharmaceuticals that are outsourced from biotechnology companies.

Single Use Support provides innovative fluid management products and services around single-use technologies for the pharmaceutical industry.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Single Use Support provides filling, draining, freezing, thawing, storing and shipping solutions for drug substances.

Our company was founded to improve drug substance processes involving single-use technologies. With innovations in the areas of bulk drug substance movements and small-volume competitive generic therapy (CGT) drug substances, we provide end-to-end solutions for the whole biopharmaceutical industry.

Single Use Support is constantly adding employees, production locations and product offerings, with the aim of delivering worry-free solutions for the whole process chain in pharmaceuticals, with a focus on the biopharmaceutical industry.

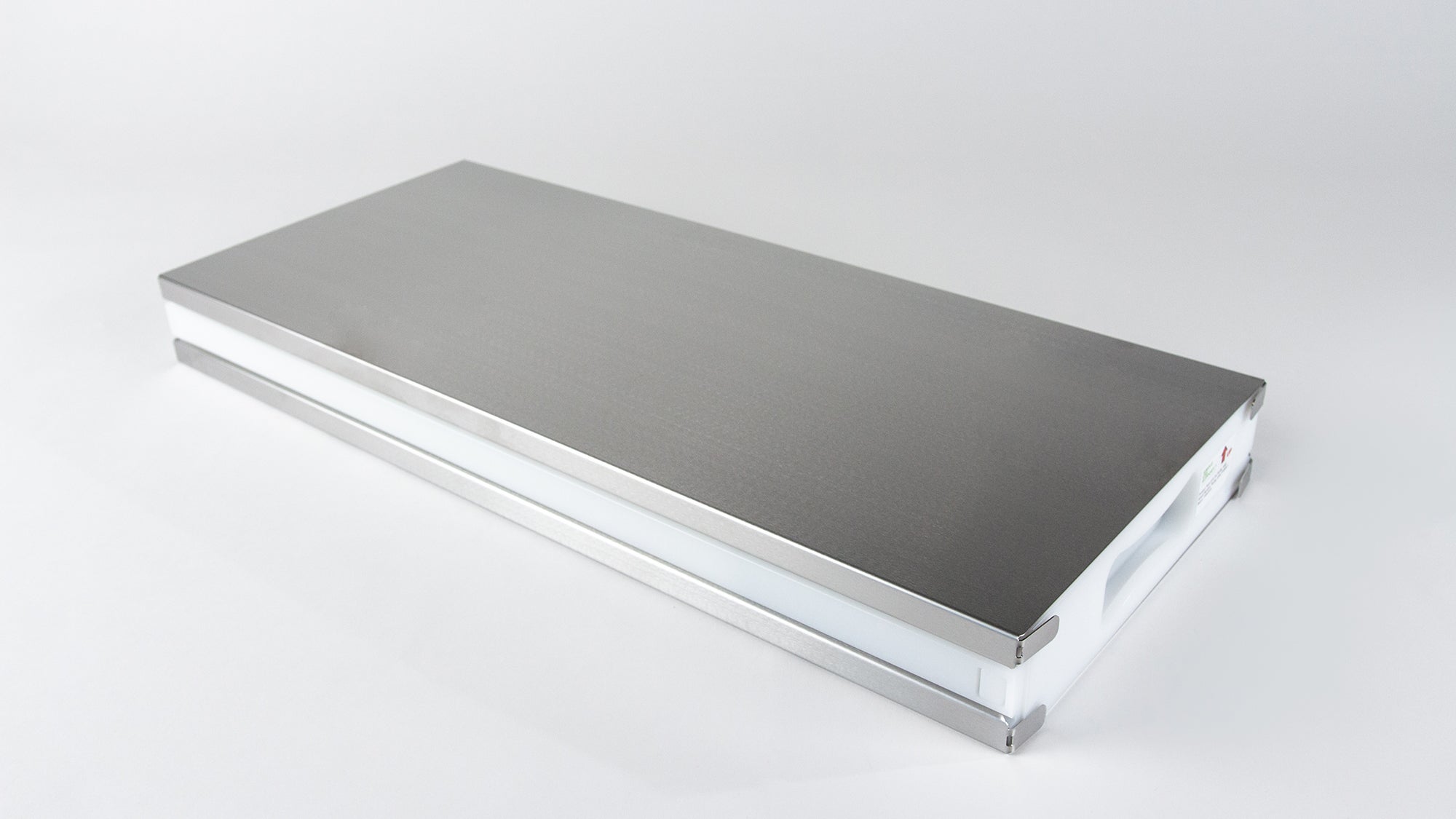

The RoSS shell from Single Use Support protects single-use bags effectively against breakages, preventing product loss and providing optimal freezing characteristics for any bag.

The system includes a heavy-duty plastic frame and stainless-steel lids. This forms a protective case for any single-use bag on the market to maximise product safety.

On the inside of the shell, the single-use bag is covered by a 3D foam that attaches its fit to the extending single-use bag during the freezing process.

Storage and transport often contain several challenges for the commercial production of biopharmaceuticals. With its flat shape, Single Use Support’s single-use bag provides the optimum characteristics for increased storage density and flexible transport solutions. They have been found to have a storage density almost four times that of bottles.

Our wide product portfolio includes several solutions that highlight the flexible possibilities around storage and shipping for drug substances using single-use technologies. The fully automated Fill and Filtration unit RoSS.FILL is designed to guarantee optimal substance filling.

RoSS.FILL’s filling platform lets you fill unlimited volumes for each batch, with a speed of up to 300l an hour. In addition, the complete filling process is fully disposable to enable a fully sterile fill and drain process.

To preserve an effective cold chain during transport, the RoSS.FRDG ultra-cold storage unit keeps RoSS shells and single-use bags cooled. The RoSS.Rack ensures safe product movement to and from various platforms.

The mixture of flexible single-use consumables such as manifolds or bags brings a number of benefits for filling, draining or storing any pharmaceutical substances. Despite this, some of the most crucial steps for product safety come between downstream and final finish processes.

The Single Use Support Bulkstream Process is designed to ensure safe and fast movement, as well as filling, freezing, storing, shipping, thawing and drainage steps.

Single Use Support was founded in 2015 by Johannes Kirchmair and Thomas Wurm. The idea was to create and establish a company that would disrupt the pharmaceutical market with innovative logistical and substance movement solutions.

The company’s starting point was the high importance of single-use bags for liquid drug substances. The major problem to solve was that of integrity, as material deficiencies, biological contamination and loss of drug substance all had to be eliminated.

Single Use Support introduced the protective RoSS® shell for single-use bags, as well as other complete platform systems for filling and draining, freezing and thawing, storage and shipping around single-use bags and bottles.

Single Use Support is based in Kufstein, Austria, and operates worldwide. Fill out the enquiry form on this page for more information.

A multinational contract development and manufacturing organisation (CDMO) with a $5bn turnover develops and manufactures pharmaceuticals that are outsourced from biotechnology companies.

The customer, a global biotechnology company with a total turnover of more than $5bn, manufactures different drug substances (BDS) of highly valuable mABs in batch sizes ranging from 10l to 700l for clinical phases up to commercialised products.

Automated filling systems are recommended by many market experts to reach the next level in drug substance management. Many users are starting automation initiatives, which is proof of an overall trend towards automated filling.

Being able to control the freezing behaviour of bulk drug substances is the ultimate goal in biopharma manufacturing.

Advanced Fluid Management for Cell Culture Freezing, Cell Banking and Cell Therapy

Traditional and rigid manufacturing processes are not suited for advanced therapies. With novel therapies pushing limits in biotechnology, the life science industry needs to keep up with adequate process solutions around the commercialisation of these specific therapies.

Seed train intensification is a flexible production process that allows laboratories and manufacturers to grow a number of cell lines for the inoculation of bioreactors used in production such as E. Coli or CHO cells.

Liquid drugs have different viscosities, degrees of sedimentation, and other varying properties, making it difficult to standardise a consistent distribution of liquids.

Five years after the Covid-19 pandemic, there are multi-faceted trends in global vaccine development that are promising for patients. Vaccine manufacturing and development have been key to improving human health and combating diseases such as polio, measles or mumps.

Single Use Support is committed to sustainability and environmental responsibility in our business operations. We believe that our innovative single-use technologies can contribute to the reduction of waste, energy consumption, and carbon footprint in the biopharmaceutical industry.

The Danish company Novo Holdings has acquired a 60% majority stake in the Austria-based company Single Use Support, thereby strengthening the company's further growth on a global level.

In the wake of the pandemic, the biotech industry is in a state of upheaval: more and more new drugs are being developed and produced. The Tyrolean company Single Use Support is actively involved in this process and continues to grow.

A study was conducted aiming to optimise the cryogenic freezing process of CHO-K1 cell line using the innovative controlled rate liquid nitrogen cryogenic freezer RoSS.LN2F. The mammalian cells were filled into 250mL single-use bags and protected by RoSS.KSET.

Fluid and cold chain management expert Single Use Support has opened a subsidiary in Lexington, Massachusetts. Equipped with a product showroom, the office will also serve as a base for increased US staff.

Single Use Support is pleased to announce that it has recently become a member of Rx-360, the International Pharmaceutical Supply Chain Consortium.

Innovative process solution provider Single Use Support continues to deliver strong organic growth, supported by an expansion in its employee base. With a successful year 2023 in the rear-view mirror, 2024 is already shaping up to be even better.

SCHOTT Pharma & Co and Single Use Support are joining forces to extensively test SCHOTT Pharma’s innovative solutions for the safe and efficient handling of small volumes of pharmaceuticals at ultra-low temperatures. Specialising in the growing sector of Advanced Therapy Medicinal Products (ATMPs), the cooperation focuses its efforts on drug delivery solutions and freezing applications for cell and gene therapies.

Single Use Support, leading provider of fluid management and freeze-thaw logistic solutions for the biopharmaceutical industry, is excited to announce its further expansion into the United States market

Filling accuracy has become increasingly important for laboratories and biopharmaceutical manufacturers. Single Use Support has developed best-in-class filling precision for aliquoting small single-use bags with its RoSS.FILL Lab Scale aseptic filling platform.

Robust Storage and Shipping – in short: RoSS – is the protective shell for all available single-use bags. Independent from manufacturer or size of the single-use bag, RoSS provides a robust, closed and 100% safe system for each bag along the process of filling, freezing, storing, shipping, thawing and draining.

RoSS.FILL is a modular platform for aseptic filling and draining of biopharmaceuticals into single-use bags and bottles.

The plate-based freeze and thaw unit, RoSS.pFTU, enabes controlled freezing and thawing of biopharmaceuticals to sub-zero temperatures. Available in different sizes to freeze few mL of drug substances up to 300L per batch, RoSS.pFTU makes scalable freezing reality.

Cold chain during mid to long term storage is maintained best with RoSS.FRDG. The cold storage refrigerator offers highest storage density for your frozen biopharmaceuticals, be it in single-use bags, bottles or vials.

Fluid management for sterile filling of biopharmaceuticals made simple.

Emerging process solution provider Single Use Support has launched RoSS.PADL, an unprecedented platform system for standardising the homogenisation and cooling of liquid pharmaceuticals.

Single Use Support specialises in providing draining, filling, thawing, freezing, shipping and storage services for drug substances.

A demonstration of the end-to-end services offered by Single Use Support, a pharmaceutical contract manufacturer based in Austria.

An overview of the production sites owned and operated by Single Use Support and the capabilities they offer.

Single-use technology has seen a rise in popularity in the pharmaceutical industry. To learn more, please watch this short video.