Delta vials and tubing glass ones are equivalent to products obtained using a different technological process. This drives some differences in terms of features and characteristics.

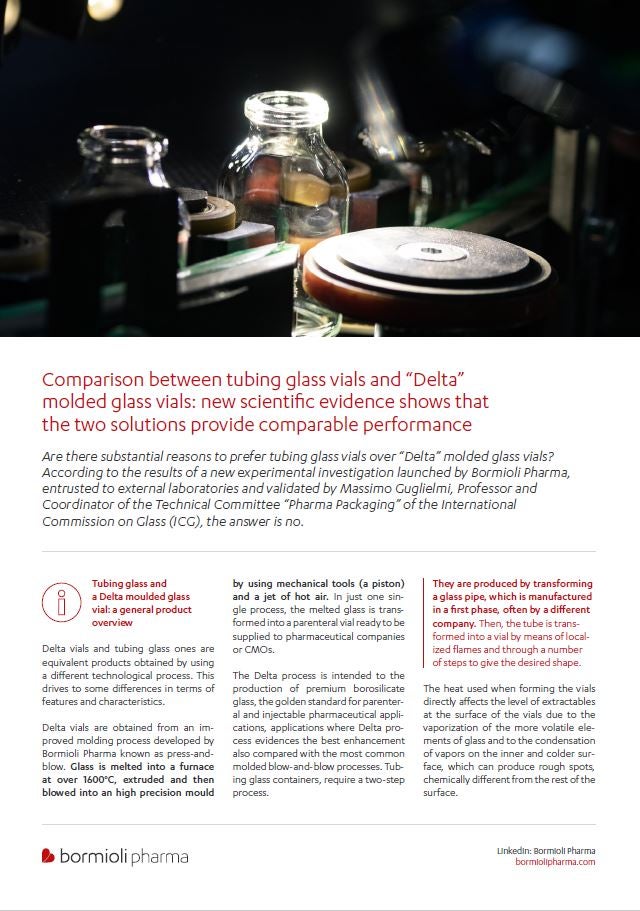

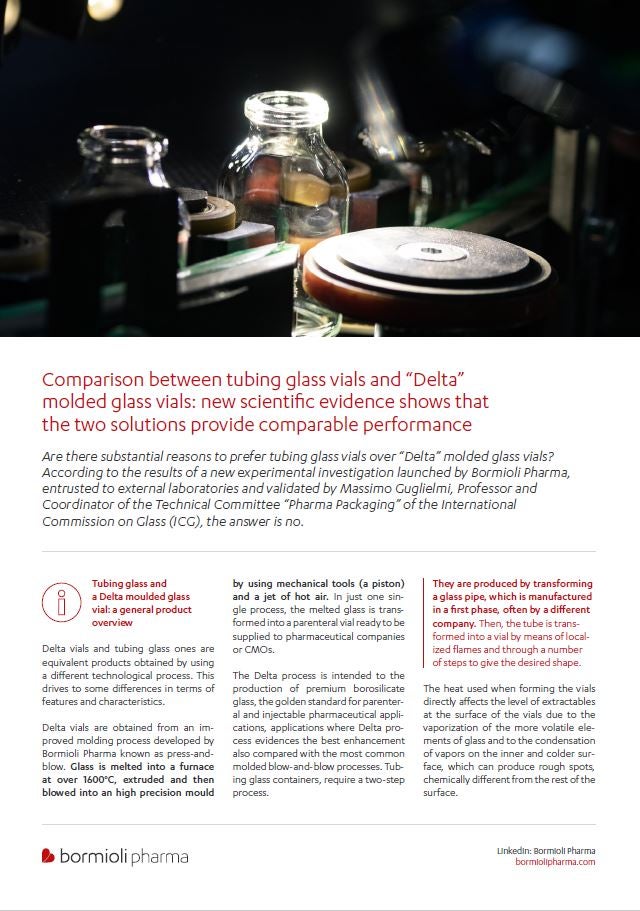

Delta vials are obtained from an improved moulding process developed by Bormioli Pharma known as press-and-blow. Glass is melted into a furnace at over 1,600°C, extruded and then blown into a high-precision mould by using mechanical tools (a piston) and a jet of hot air. In just one single process, the melted glass is transformed into a parenteral vial ready to be supplied to pharmaceutical companies and CMOs.

To read more, please download this free white paper.