Case Study: How Origin Supported Pharmaceutical Manufacturer Start-Up

This white paper showcases a case study demonstrating how Origin Pharma Packaging worked in collaboration with a new pharma start-up.

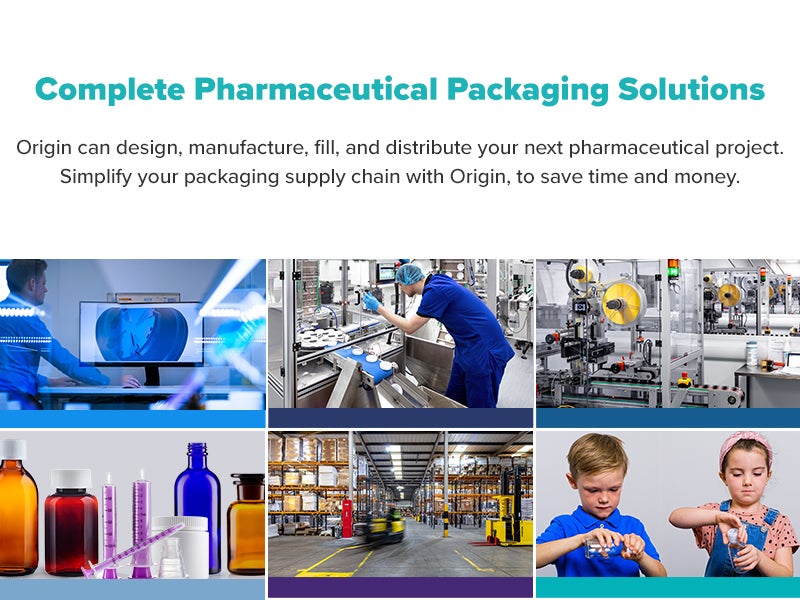

Origin Pharma Packaging (Origin) designs, manufactures, and supplies packaging for pharmaceutical products.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Origin Pharma Packaging (Origin) designs, manufactures, and supplies packaging for pharmaceutical products.

Operating from its Pharmaceutical Packaging, Logistics & Innovation Centre, the company partners with licence holders and contract manufacturing organisations (CMO) to provide innovative designs, strategic production, and strong supply chain performance.

Origin’s ethos is ‘Everything we do, we innovate’. This applies from designing new child-resistant closures for major pharmaceutical companies, to state-of-the-art enterprise resource-planning systems to increase speed-to-market.

Whether for a new packaging design, or an established supply chain, Origin offers innovative, highly flexible, and cost-effective packaging solutions, with assured supply. Origin provides a consistent and integrated approach to creating compliant and effective packaging.

The company forms strong partnerships with drug manufacturers, consumers, and healthcare companies, which gives Origin a clear sense of what its key deliverables should contain. Since its inception in 1963, Origin’s focus has been consistently developed to assist the formation of effective packaging solutions, which are supported by a strong supply chain and outstanding client services activity. Its teams challenge design, manufacture, and distribution to ensure new designs lead innovation, rather than imitate.

The company is also extremely flexible, capable of creating strong primary packaging solutions to any problem worldwide. Origin employs world-class innovators, with a large wealth of experience, who deliver value beyond customers’ and partners’ most demanding expectations. While the company excels as a supplier, manufacturer, and designer, it also drives productivity and profitability for pharmaceutical companies, adapting to any business formation and size.

Origin’s Hybrid Pharma Packaging Partner (HP3) model is a programme for the management of change management, designed to raise the performance of the pharmaceutical primary packaging industry’s supply chains to improve the competitiveness of the market. This allows Origin to provide flexible and personalised solutions for clients, delivering new designs quickly.

In addition, Origin has developed the ‘Product. Intelligence. Learn. System’ (P.I.L), which allows new product development (NPD), sales, marketing, and operation teams to gather ideas and formulate a solution.

Origin is flexible and can provide assistance throughout the complete primary packaging development process, true to its value ‘Bringing Healing Home’. The company combines its extensive knowledge and experience with high-quality supply chain networks, innovation, design, and manufacturing to increase speed-to-market of packaging and raise profits.

HP3 is a supply partner that embraces all aspects of design, manufacture, and the supply chain.

HP3’s benefits include:

Origin’s UK NPD team supplies and manufactures child-resistant packaging, offering a large range of medical packaging for pharmaceuticals that meet and exceed BSEN ISO:8317 and 16CFR1700 certification requirements, as well as international guidelines, regulations, and laboratory tests. These standards have both ethical and commercial significance, preventing the possible devastating effects of accidental child drug ingestion and preventing brand damage.

The company has expertise in plastic closure designs and the supply of child-proof caps. The NPD team’s extensive knowledge and passion is infused with a deep resolve to ensure child safety worldwide. Origin works closely with the Child Safe Packaging Group (CSPG), which brings to light the incidents and traumatic experiences of accidental drug ingestion that can change the lives of those involves. Origin is committed to prevent these occurrences by preventing more than 40 million ingestions a year through its effective and compliant child-resistant packaging formations.

A dedicated global pharmaceutical packaging design organisation, Origin creates compliant, high-quality pharmaceutical packaging with quality assurance (QA) and good manufacturing practice (GMP) standards to meet regulatory supply requirements. Products are also designed to meet pharmaceutical drug manufacturer’s standards, while also increasing their speed-to-market for commercialised drugs.

PILOT is a key element of Origin’s HP3 Hybrid operating system. Designed to ensure Origin captures everything it needs to know about your latest pharmaceutical packaging, PILOT’s innovation is inspiring. It invokes powerful attributes, including passion, emotion, pride, and belief. Origin believes in success and the company refuses to limit its knowledge to a single production process, a particular material, or polymer.

Origin’s innovations include manufacturing advanced material compositions, creating precision 3D printed prototypes, and manufacturing using multi-layer extrusion-moulded processes capable of overcoming migration issues previously unresolved. PILOT provides an essential means of control.

Origin’s multi-faceted activities in these fields all combine to make Origin unique. Rather than operating from one location and in one narrow field of expertise, Origin operates from dedicated production cells strategically located in the EU and the US. This gives the company almost unlimited flexibility in its production processes, enviable lead times, and in many cases localised stock holding.

Utilising a top-class pharmaceutical packaging team, Origin guides client’s packaging innovations from inception to design, tooling, clinical trials, validation, production, assembly, and marketing, constantly re-addressing best practice for a fully personal experience.

Origin is trusted daily to be innovative, while addressing a client’s needs and protecting what’s important. Working with Origin minimises the risk of failure in child-safe testing, as the company has engaged in child-resistant packaging development for half a century and has gained a wealth of experience in effective designs.

If you are looking for industry leading packaging, if you want guidance on packaging and the advantages of the types of products we design and produce, or if you require examples or a quote, then get in touch with Origin today using the enquiry form.

This white paper showcases a case study demonstrating how Origin Pharma Packaging worked in collaboration with a new pharma start-up.

It’s very easy to go about your day-to-day life without thinking about the impact the products you buy and use have on the environment.

Child-resistant packaging is a critical component of producing and selling hazardous substances such as pharmaceuticals and toxic materials.

The Merck Wilmington Biotech facility in Delaware, US, is expected to be fully operational by 2030.

Merck expanded its cell culture media production facility in Lenexa, Kansas, with an investment of €23m ($25m).

Fusion opened a radiopharmaceutical facility to produce targeted alpha therapies (TATs) for cancer in Hamilton, Ontario, Canada.

In a world increasingly conscious of environmental impact, businesses in every sector are being called upon to re-evaluate their processes and adopt more eco-friendly solutions. Nowhere is this more pressing than in the pharmaceutical industry, where sustainable packaging is fast becoming a top priority. As pharmaceutical products are essential to our daily lives, how they are packaged plays a significant role in shaping the industry’s environmental footprint.

Pharmaceutical packaging plays a critical role in the health and safety of the public, ensuring the protection, delivery, and information of medical products. As the pharmaceutical industry grows more complex, so too does the packaging that supports it. But what is pharmaceutical packaging, and why is it so essential?

Origin is proud to introduce ClicCan®: the next-generation child-resistant packaging solution for nicotine pouches. Designed to meet rigorous international safety standards, ClicCan® protects against accidental exposure while seamlessly integrating into your existing production lines.

All parents know that young children have a deep curiosity about the world around them, and love nothing more than to explore. Unfortunately, there are a surprising number of items around the home that might pose a health or safety concern if they’re discovered by little hands. That’s why child-resistant packaging is an essential investment for any business selling products that might be dangerous for children.

Tamper-evident packaging is a form of packaging, which is designed to protect products and provide additional security for users. Tamper-evident packaging is used in many industries, and it offers a wide range of benefits for organisations and their customers. In some sectors, such as pharmaceuticals, companies must adhere to government requirements linked to the use of tamper-evident primary packaging, while in other sectors, it provides security throughout the supply chain and purchase by the consumer.

Origin is proud to announce that we have continued our Silver Patronage of the Child Accident Prevention Trust (CAPT). Our ongoing support of this dedicated charity is helping to improve child safety and bring life home for children.

Global pharmaceutical solutions provider, Origin, has announced the opening of a new high-capacity aseptic facility for filling, labelling and packaging IVD’s and healthcare products in Melton, East Riding of Yorkshire.

Origin Pharma Packaging has opened a new warehouse facility in Scunthorpe, North Lincolnshire, expanding on its logistics and storage site in Melton, East Riding of Yorkshire.

Last year, there was significant focus on the pharmaceutical industry as the race for Covid-19 treatments and vaccine began. With vaccines now in distribution worldwide, it’s time to look at what 2021 could bring.

In this article, Origin Pharma Packaging, manufacturer and provider of innovative packaging solutions for the healthcare industry, discuss counterfeiting in the pharmaceutical industry and how to combat it.

Origin Pharma Packaging is pleased to showcase the addition of its dedicated cleanroom environment.

The US Food and Drug Administration (FDA) has granted Origin a licence to export registered medical products to the US.

GSK, Bristol-Myers Squibb, Novartis and AstraZeneca to name but a few are investing billions of dollars in biologics to have prime mover advantage in a market forecast to be worth nearly $480bn by 2024.

As legislation and ethical awareness evolves, Origin Pharma Packaging has seen the demand for innovative design and production of child-safe packaging increase on a global scale.

Meeting in Nairobi in December 2017, the UN Environment Assembly committed to a new resolution, urging all countries to prevent and significantly reduce marine pollution of all kinds, in particular from land-based activities’ by 2025. It claims, unless action is taken, oceans will contain more plastic than fish by 2050.

The CPhI Pharma Awards has announced the finalists and Origin Pharma's child-resistant, tamper-evident, blister pack wallet SmartX has been selected for 'Excellence in Pharma: Packaging', making it a hat-trick of finalist nominations in 2017.

Origin has announced it will be attending the GLOBAL CPhI event in Frankfurt, Germany

Origin Pharma Packaging has announced it is launching a child-resistant and tamper-evident blister pack wallet at CPhI North America and has released a new official video.

Origin has launched a new video, which showcases its Pharmaceutical Packaging Design Process.

Origin Pharma Packaging has launched a new packaging design and innovation zone on its website to help support new device and packaging projects.

Origin Pharma Packaging has been chosen as a finalist for the CPhI Pharma Awards out of more than 100 leading companies in the Pharmaceutical industry.

Origin Pharma will be exhibiting within the Innopack Hall of CPhl Barcelona.

Origin Pharma Packaging talks child safety compliance and how it helps eradicate unsafe packaging in the UK pharmacy market.

Origin Pharma Packaging has invested and brought in-house a dedicated 3D printing department to allow clients to see the creation of pharmaceutical packaging concepts within a matter of hours.

Origin Pharma Packaging has explained its dynamic pharmaceutical packaging design process and the importance of getting primary packaging designs right the first time around.

Origin Pharma Packaging will be exhibiting at the CPhI Barcelona, where it will launch its latest packaging innovations.

Use of 3D printing is varied and ever-changing, with many companies in a number of sectors utilising the technique to improve systems and techniques.

Origin Pharma has designed a creative solution for the pharmaceutical industry supply chain, the Hybrid Pharma Packaging Partner (HP3).

Origin Packaging has received confirmation that the ISO Board of Certification approved Origin's ISO 15378 certification.

In-house market-leading aseptic filling – 7 ISO 5 filling environments

Combining design and manufacturing services to keep your costs down