Product Portfolio for Range Device Assembly Machines

Highly flexible and scalable platforms for assembling, labelling and secondary packaging

Syntegon supplies intelligent solutions for the production, processing, filling, inspection, and packaging of pharmaceuticals.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Processing and packaging for a better life is what Syntegon’s employees work for every day. Be it with individual machines, systems, or services, Syntegon helps its customers in the global pharmaceutical and food industries to improve people’s lives.

Syntegon’s intelligent solutions for the pharma sector enable the safe and high-quality production, processing, filling, inspection, and packaging of both liquid and solid pharmaceuticals. Our focus is on developing sustainable packaging solutions, reducing the energy consumption of our machines, and pursuing ambitious goals to lower our emissions.

With 1,100 service experts and a comprehensive service portfolio that covers the entire machine lifecycle, from spare part management to digital line optimisation, Syntegon lays the foundation for smooth production processes for all its customers.

Syntegon’s pharmaceutical portfolio covers formulation, processing, sterilisation, fill-finish, barrier systems, and inspection for liquid pharmaceuticals, as well as processing, capsule filling, tablet pressing and coating for oral solid dosage forms. Our solutions reduce time to market for drug development and safeguard the quality and availability of existing medicines.

Syntegon provides various forms of packaging for pharmaceutical products, including ampoules, cartridges, syringes, capsules, tablets, sachets, and stickpacks. We also supply vials for both dry and liquid products, as well as packaging solutions for powder, granules and pellets.

Syntegon develops packaging technologies for liquid-dose pharmaceutical products, including cleaning, depyrogenation, liquid fill/finish, freeze-drying, and process sterilisation systems. Our liquid fill and finish solutions include filling systems for ampoules, cartridges, syringes, liquid vials, and dry vials.

Our subsidiary Pharmatec supplies pure media solutions for processing pure water, high-purity water, water for injection, and pure steam. These solutions provide all the components of a fully integrated system infrastructure, from hot and cold generators to storage and distribution systems.

Syntegon offers solid-dose pharmaceutical packaging systems such as fluid bed systems and high-shear mixers, as well as machines for capsule filling, checkweighing, tablet compression, tablet coating, and continuous manufacturing. We also provide systems for the vertical forming, filling, and sealing of powder and granules.

Syntegon can offer the appropriate process technology for producing pharmaceutical, health and nutrition products, whether they involve filling powders, tablets, pellets, granules, liquids, or other combinations into hard shell capsules (hydroxypropyl methylcellulose or gelatin). Our capsule filling machines provide the ideal conditions for pharmaceutical products of the highest standards, from research and development or pilot-scale to high production volumes.

Based in Waiblingen, Germany, Syntegon has been active for more than 160 years and registered annual sales of €1.4bn in 2021. The company operates more than 30 sites in almost 20 countries, employing a total of 5,800 colleagues.

For more information about our products and services, please make an enquiry via the form on this page.

Highly flexible and scalable platforms for assembling, labelling and secondary packaging

The injectable drug delivery market has experienced a paradigm shift in recent years. Due to drastic changes in lifestyle and the accompanying increase in chronic diseases such as diabetes, the demand for injectable drugs has been growing for decades.

Syntegon Technology is your reliable partner for process and packaging technology in the global pharmaceutical and food industries.

Individual machines, systems or services – as a full-service provider, Syntegon takes responsibility right up to fully integrated end to end solutions.

High-purity media systems are essential for the production of liquid pharmaceuticals. At Syntegon, we rely on our globally proven Pharmatec expertise.

Schoeller-Bleckmann Medizintechnik (SBM) specialises in the development and production of sterilisers and freeze dryers for the pharmaceutical industry.

Syntegon is at your side from project planning, development and implementation to comprehensive digitisation, qualification and validation services.

Syntegon’s ALF 5000 is a flexible, efficient filling and closing machine for the high-performance range. In addition to an increased output of up to 600 containers per minute, the ALF 5000 delivers an optional 100% in-process control for vials and a hygienic design. Its other advantages include easier cleaning and high safety.

Freeze-drying systems are necessary for the stabilisation of thermolabile and sensitive products such as oncological drugs, vaccines and antibodies. The modular construction, in both the vertical and horizontal design, enables flexible coverage of the entire range of GMP-compliant systems, from small production volumes to large production batches.

Syntegon and Lighthouse Instruments have combined their complementary strengths to offer an automated platform for precise and gentle leak detection and closure integrity testing using laser-based headspace analysis (HSA). Laser-based HSA is the preferred leak detection method for products filled under vacuum or purged with inert gases, as well as parenteral products.

Syntegon’s KLD Series detects leaks in ampoules and vials at up to 24,000 containers per hour. The high-voltage leak detection method is based on electrical current measurement on the mA scale, and involves applying voltages of up to 30kV across containers filled with conductive liquids. An increased electrical current indicates a breach in the isolating container wall.

The USM 6011 and 6015 are designed for the fast de-traying and retraying of syringes and cylindrical cartridges from rondo trays. Syntegon’s hygienic machine design allows handling of empty and filled products.

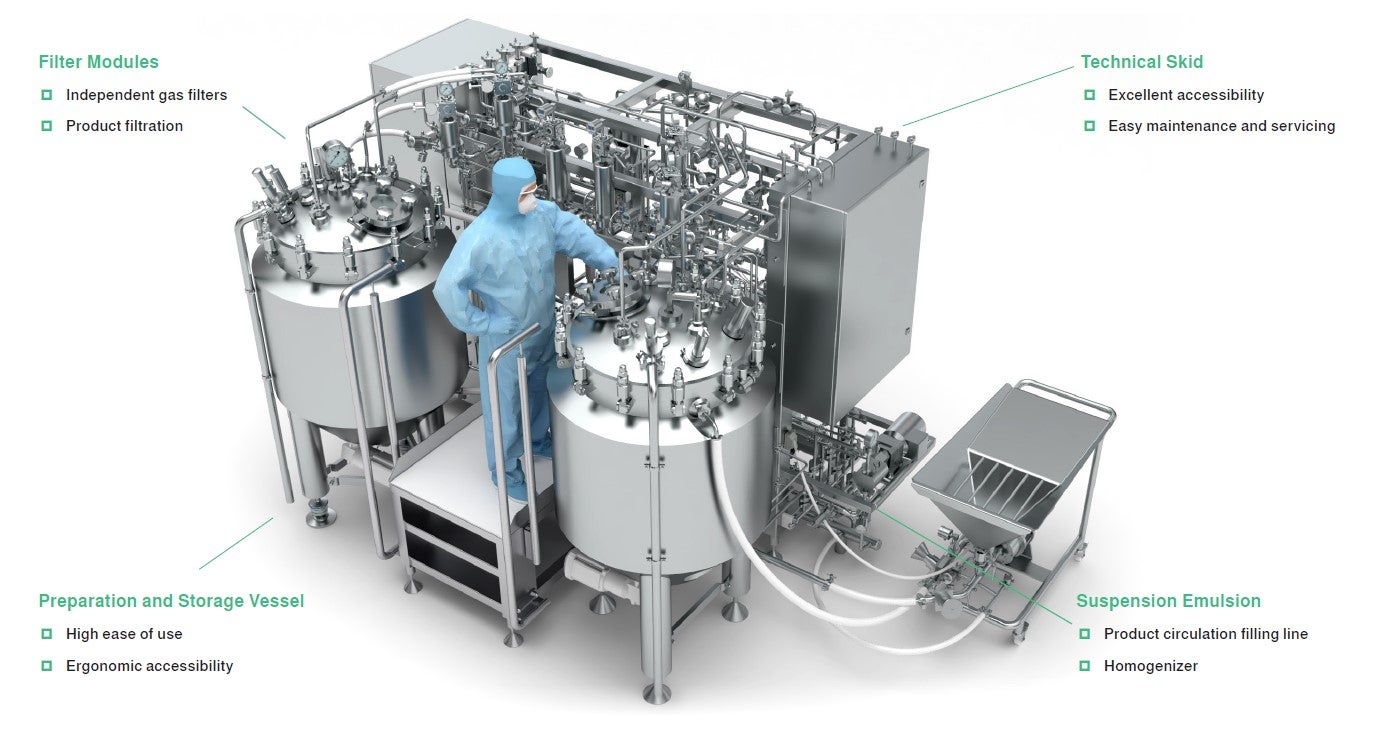

Syntegon’s SVP Essential Formulation System is a fully integrated and automated formulation system that provides GMP process flexibility with unparalleled speed and convenience. It is an efficient base-variant of the proven SVP System designed to provide the highest quality of formulation services, drawing on decades of experience in the engineering and design of process systems.

Syntegon’s AIM Automated Inspection Machines offer the best quality inspection services powered by artificial intelligence. Both camera-based inspection and SD technology are integrated in highly modular, compact devices to enable high-performance and flexible visual inspection.

Syntegon’s Versynta Flexible Filling Platform (FFP) is based on pre-developed and tested modules that can be flexibly combined. The machine offers a lean and complete solution for the entire filling process from a single source, including an integrated isolator technology.