GMP Compliant Filling of APIs - No Cleanroom Required

GMP Compliant Filling of APIs - No Cleanroom Required

Dec is a global provider of powder handling systems to the pharmaceutical and chemical industries. Its turnkey and custom-designed solutions have been successfully integrated into complex operations in hundreds of companies worldwide, both multi-nationals and specialists.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Dec is a global provider of powder handling systems to the pharmaceutical and chemical industries. Its turnkey and custom-designed solutions have been successfully integrated into complex operations in hundreds of companies worldwide, both multi-nationals and specialists.

The Dec range covers every facet of powder handling, including:

Safety, productivity and containment are key considerations, with ease of cleaning also being a priority. The PTS powder transfer system provides safe and contained powder transfer, with a wide range of applications in addition to reactor charging.

The DCS drum containment system provides a safe and contained method of filling and emptying drums, big bags and continuous liners. It also has the capability of emptying process equipment and filling packaging in one step.

The DCS Liquid handles liquids which require strict odour control or toxic liquids.

Precise big bag filling / emptying in combination with a PTS feeder is also provided by the DCS system. The PTS feeder provides a single-step solution for filling, emptying and dosing bags, drums and big bags.

The contained bag station combines the advantages of isolation technology with laminar flow technique, providing a high containment solution for emptying multiple bags.

The suction hopper can be connected to various items of equipment. Working in combination with the PTS powder transfer system, it provides easy discharge of poor flowing powders (e.g. lumpy, wet, etc.).

Dosing of powder into a selection of receivers or packaging demands high levels of handling flexibility. The PFL Powderflex system allows continuous and precise dosing of small to medium quantities.

Dec’s unique microdosing technology provides high-precision dosing for a wide range of requirements.

The PTS feeder provides a single-step solution for filling, emptying and dosing bags, drums and big bags.

Today’s processes demand the flexibility to swiftly mix powders with different characteristics, often within a contained environment.

The Batchmixer, which is based on the PTS technology, has been tested in a two-year research study at a Swiss University. The results are revolutionary, providing a machine that is easily integrated.

The MPTS micro powder transfer system, which is based around the PTS technology, allows operators to take representative and homogeneous samples of toxic powders automatically in a contained environment, even in areas where personnel have no access.

Dec’s versatile and multi-format micronizers from small-scale to full-size production are available in open and contained arrangements with the ability to handle difficult products, e.g. Triam family, Fluticasone or Orlistat, etc. Systems are provided in sterile, toxic or sterile toxic arrangements in contained or non-contained format. New revolutionary technology achieves a particle size distribution (PSD) below 5µm.

Dec is specialized in containment; our solutions take account of the operator’s optimal protection, cGMP guidelines, the elimination of cross contamination and the reduction of clean-up requirements.

Dec’s services include:

GMP Compliant Filling of APIs - No Cleanroom Required

Bidachem SPA is one of the major manufacturers of fine chemicals and active pharmaceutical ingredients (APIs) in Italy.

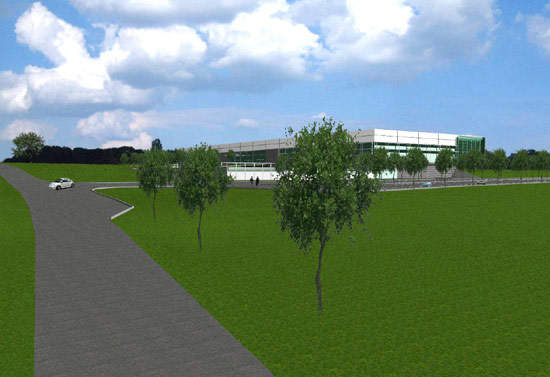

Ferring Pharmaceuticals announced its intention in 2003 to build a new production site at Saint-Prex, Canton of Vaud in

Lonza Biotec completed the construction of new manufacturing capacity with a multi-product design at Visp in Switzerland

Schering-Plough has continued to capitalise on its investment program into facilities based in Singapore. The company cu

In March 1999 Rohner AG began the construction of a new state-of-the-art pharmaceutical facility at its existing site at

The large-scale pharmaceutical facility in Tuas, Singapore, is Pfizer's first manufacturing facility in the country.

The project is a pharmaceuticals plant located at Snackviken, in Södartälje, Sweden. It is owned by AstraZeneca, which was formed by a merger of Swedish Astra and British Zeneca.

If you are handling any of these: Waste toxic liquids, Calcium Hypochloride, Benzyl Sulphonyl Chloride, Propionyl Acetyl Chloride, MED, DICI, EMCA, Toluene, CH2CI, HCI, TMCS, Methylenchloride, Acetone, Methylacetate, Pyridine, BSTFA, Methanol, IMS, Dioxane, Acetonitrile, MD, Heptane, Methylchlorformiate, or other toxic or corrosive liquids you need DCS Liquid.

The safe and efficient filling and emptying of big bags is a challenge for many users but Dec now offers the ideal transfer solution.

The launch of the DEC MicroJet 10, the world's smallest fully functioning jet mill, now completes our research and development range of jet mills.

GSK Montrose is a 45 acre site located on the coast in Angus, Scotland. The site performs primary manufacture of active pharmaceutical ingredients and specialises in respiratory, steroid and anti viral products that are shipped to customers worldwide. In the summer of 2009, GSK had an i

Dec now offers a much anticipated solution in the volumetric dosing of small quantities of powder. The product is filled in a calibrated chamber of variable volume by action of vacuum, and emptied mechanically either by a piston or by applying pressure. The Micro PTS is based on the PTS technolog