Accelerate Process Understanding, Innovation and Time to Market in Biotech

Our slogan is 'Bring data to life', and we have been doing exactly that with biotechnology companies and research institutes around the world for years.

In order to reduce costs and improve product safety, advanced analytics tools traditionally used by analytical groups are being transferred to the plant floor, to help pharmaceutical manufacturers reduce process failures, accelerate technology transfer, improve yields and monitor quality.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

In order to reduce costs and improve product safety, advanced analytics tools traditionally used by analytical groups are being transferred to the plant floor, to help pharmaceutical manufacturers reduce process failures, accelerate technology transfer, improve yields and monitor quality.

Multivariate data analysis (MVA) is the investigation of many variables simultaneously, to understand the relationships that may exist between them. Although this method has been around for many years, its application in production processes is relatively new, but now manufacturers are realising that the data collected during production operations offer fascinating insights into product development, process performance and quality control.

Pharmaceutical manufacturing processes tend to be highly multivariate in nature so they require multiple measurements to fully understand them. Most statistical process control (SPC) systems rely on univariate methods, which only look at single variables, one at a time, and these methods are not sufficient for analysing complex systems. Multivariate analysis tools allow engineers and production managers to better understand process behaviour and implement more robust control strategies, enabling them to:

With CAMO’s solutions multivariate models can be applied to real-time production processes and used either standalone to analyse off-line data, connected to databases or scientific instruments (e.g. spectrometers), or integrated with control systems for use by process operators.

CAMO Software is a leading provider of multivariate data analysis software and solutions, and is the creator of the Unscrambler® X suite of products. Unscrambler X multivariate analysis software is used by engineers and data analysts all over the world. It includes powerful regression, classification and exploratory data analysis tools, in addition to an integrated design of experiments module.

A hierarchical model development module, which is available as a software plug-in for the Unscrambler X, offers a powerful decision-tree approach to multivariate modelling of complex data. It allows you to join classification and prediction models, saving time and improving efficiency in the modelling of non-linear data.

Process Pulse is a real-time process monitoring software that lets you predict, identify and correct deviations before they upset the production process. With this cost-effective, versatile and easy to use software, multivariate models can be applied to at-line, on-line or in-line processes.

CAMO’s Prediction Engine and Classification Engine software can be integrated directly into analytical or scientific instruments for real-time predictions and classifications directly from spectrometers using multivariate models.

Enterprise solutions from CAMO Software enable you to apply powerful multivariate models across your R&D, production or QA/QC operations. These customisable solutions can be integrated with instruments, process equipment and control systems according to your requirements.

If you have a lot of data but do not have the resources or time to analyse it, CAMO can help. Our consultants offer world-leading data analysis combined with hands-on industry expertise and experience.

Our training courses can help you use multivariate analysis more effectively, in order to get more value from your data. Classroom, online or tailored in-house training courses are available, and we cater to all levels of experience, from beginner to expert.

Manufacturers who adopt these tools can quickly see improvements in their operations and bottom line, including:

Our slogan is 'Bring data to life', and we have been doing exactly that with biotechnology companies and research institutes around the world for years.

Multivariate data analysis (MVA) and design of experiments (DoE) are advanced analysis techniques which enable biotech organisations to improve their data analysis and optimise operations across the product lifecycle.

The Unscrambler® X Process Pulse II can be utilised in all levels of an organisation, providing solutions to a variety of challenges using real-time process monitoring.

In 2004, the FDA issued the process analytical technology (PAT) framework guidance in order to support innovation and efficiency in pharmaceutical development, manufacturing and quality assurance.

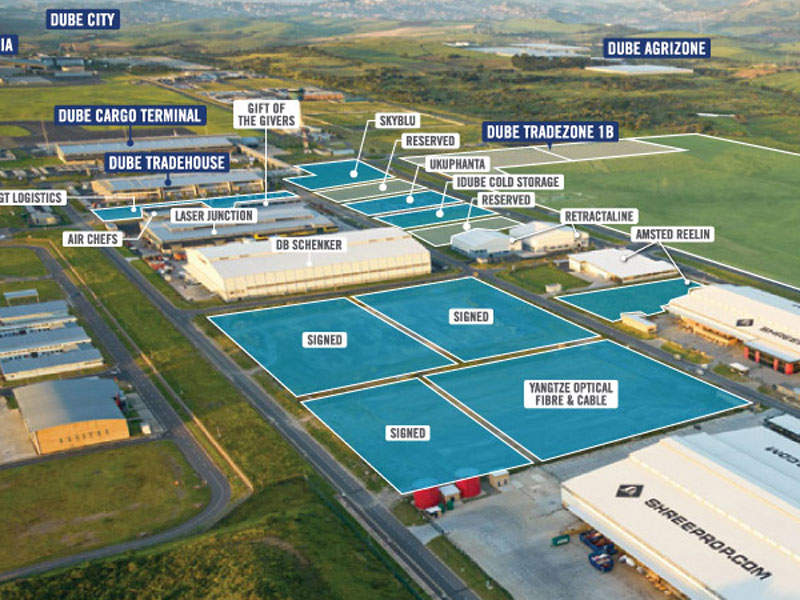

India-based pharmaceutical company Cipla has announced plans to build a manufacturing facility in Durban, KwaZulu-Natal, South Africa.

CAMO Software has launched a new version of its all-in-one multivariate data analysis (MVA) software, the Unscrambler X.

CAMO Software (Woodbridge New Jersey) has appointed IBS-Caribe as their reseller in Puerto Rico.

CAMO Software has announced the release of a new version of their easy-to-use multivariate process monitoring solution, Unscrambler® X Process Pulse II.

CAMO Software has announced the launch of service pack 2014 for the all-in-one Multivariate Data Analysis (MVA) and design of experiments (DoE) software, the Unscrambler X.

CAMO Software and Lonza Group have entered into an agreement where CAMO will deliver a PAT software solution for collecting, handling, storing, monitoring and modelling data.

Improve modelling of complex data with the powerful Hierarchical Modeling software.

The Unscrambler X has set the standard for multivariate analysis (MVA) and design of experiment software for more than 25 years.

Unscrambler X Classification Engine runs classification models directly from analytical instruments.

Unscrambler X Prediction Engine allows predictive models to run directly on a spectrometer or control system, using models generated off-line with the Unscrambler X.

Process Pulse software improves process monitoring, understanding and control.