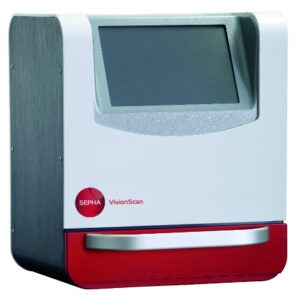

BottleScan – Integrity Tester for Induction-Sealed Pharmaceutical Bottles

BottleScan is a tool-less, non-destructive multi-bottle integrity tester for induction-sealed pharmaceutical bottles.

Features and benefits include:

- Non-destructive inspection device that detects defects in bottles and induction seals down to 15µm, dependent on bottle type

- Tests up to four bottles per test cycle in a test time of 30s-90s

- Operating system can store up to 30,000 product types

- No tooling required so ideal for production lines with multiple products

- Quick, repeatable test with objective pass / fail results

- Audit data available and can form part of 21CFR Part 11 compliant system

- Can handle multiple bottle sizes

- Configurable methods allow user to decide machine sensitivity

- Simple operator use with minimal training required