Sepha Partners with Parle Global Technologies

Sepha is delighted to announce it has partnered with Parle Global Technologies for the distribution of its specialist apparatus utilised in the production of pharmaceutical blister packs, medical devices and healthcare products, in the Indian market and neighbouring regions.

With its headquarters based in Mumbai, India, Parle represents a wide range of global pharmaceutical equipment manufacturers and has a reputation for delivering high-quality products and service excellence in the Indian market. The company has been one of the leading suppliers of machines, tooling and spares for over 40 years.

Head of Sales and Marketing, Paul Smith, is excited about the new partnership: “In Parle we have found the perfect distributor and partner. Their depth of knowledge and experience of the Indian market and the bordering countries will be invaluable to Sepha to continue to grow in this market. Alongside Parle’s extensive range of existing products, our range of leak test, deblistering and small packaging solutions offer the ideal fit for both companies”.

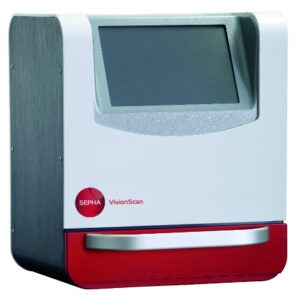

India has an important position in the global pharmaceutical industry as it’s the largest provider of generic drugs globally. Parle expects high demand for the range of leak test equipment including the Sepha VisionScan blister leak test solution and Multi-Q, Container Closure Integrity Testing system. Many pharmaceutical manufacturers require low cost, yet deterministic and non-destructive alternatives to blue dye leak testing that can easily be integrated into their quality control solutions”.

The company also has high expectations for small blister packaging machines including the Sepha EZ Blister that enables manufacturers to make small batches of blister packs. These tabletop blister packaging machines which will be of particular interest for R&D purposes, new product development and clinical trials.

There is also a great business opportunity for Sepha’s range of deblistering solutions to provide pharmaceutical manufacturers with an easy way to recover product from rejected blister packs. The active product can be separated from waste packaging before disposal, reducing waste disposal costs.

For more information, please fill out the enquiry form attached to this page.