Solving Complex Pharmaceuticals Dosing Tasks

For dosing and filling in the pharmaceutical industry, you usually think of water-like, non-viscous products such as solutions for injecting.

ViscoTec provides solutions for shear filling, conveying and metering of pharmaceutical fluids, including liquids and semi-solids.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

ViscoTec provides solutions for low-shear shear filling, conveying and metering of pharmaceutical fluids, including liquids and semi-solids.

ViscoTec’s Pharma-Dispenser series meets good manufacturing practices (GMP) and hygienic standards to ensure optimal design and documentation. It also holds a European Hygienic Engineering and Design Group (EHEDG) certificate.

The company’s range of used elastomers is certified to FDA requirements and all metallic components meet DIN EN 10204 specifications.

They are perfectly suited for low viscosity fluids to semisolids for:

ViscoTec’s pharmaceutical dispensers feature high-quality cleaning properties and are easy to disassemble.

All wetted contact parts that can be sterilised in an autoclave to protect materials against harmful environmental influences. It also protects the environment against product leakage as the seal is equipped with a locking chamber.

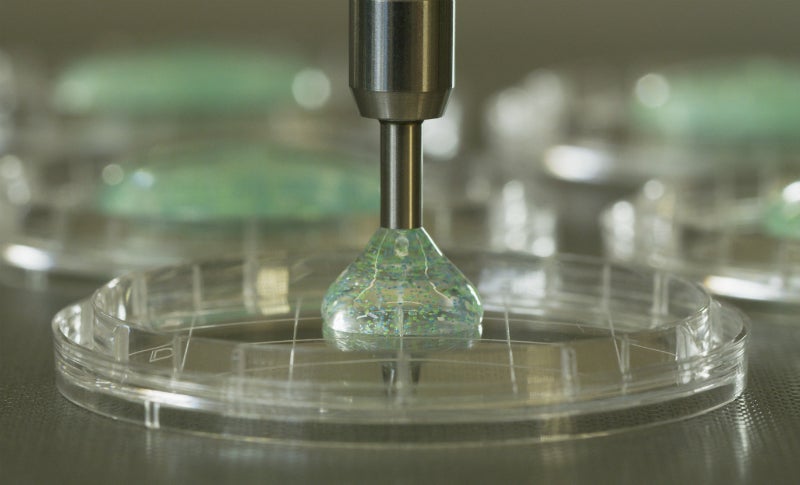

The VPHD series was specially developed for applications in the pharmaceutical and biotechnological industries.

Pharmaceutical control helps to main the flow rate and desired dosing volume with a simple and accurate system. The dosing volume, speed, calibration and suck-back at the end of dosing can be set using the touch panel. Accuracy of the dosage is more than 99%.

Control through a higher level is possible at any time. SPS transfers the parameter via profibus to the pharmaceutical control.

To meet requirements of cycle times in the pharmaceutical production of filling quantities between 10ml and 20ml, the 2VPHD12-3D Pharma-Dispenser is available in larger volumes.

Compared with dispensers of the same size, the capacity is increased by 300% and is available up to 714ml/min. The dispenser is suitable for integration in syringe filling lines of high-viscosity hydrogels.

Due to one second cycle times to fill 10ml of gel, the dispenser integrates itself into the required filling process.

ViscoTec’s dosing and filling units are based on the endless piston principle from a group of rotary positive displacement pumps.

The company’s rotor / stator geometry maintains a constant volume proportionate to the rotation angle per revolution. The volume is defined by the angle of rotation of the rotor.

The flow direction is reversible by changing the direction of rotation, ensuring the pump curve is stable, pulsation-free and linear. This feature enables users to understand the ratio between revolution, time and volume rate, resulting in dosing accuracy of 99% at the pump outlet (depending on the fluid).

ViscoTec’s dosing chamber keeps the volume constant during motion, dispensing solid-containing fluids and shear-sensitive, chunky products.

In more than 95% of applications, there is no need for filling or dosing valves as a short reverse motion at the end of the dosing process prevents dripping.

ViscoTec serves a range of industries, including the pharmaceutical, medical, biochemistry, automotive, aerospace, electronic engineering, food and cosmetic sectors.

Clients benefit from the company’s technology as it provides reliable, accurate and fast dosing that helps to increase the quality of their products.

For each application, the client receives comprehensive advice from ViscoTec specialists and experts to achieve the best results. The company offers support and an optimum service to guarantee that products are tailored to match the application.

ViscoTec won the ‘Bayerns Best 50’ award in 2014 and the ‘Best of Industriepreis’ award in 2015.

For dosing and filling in the pharmaceutical industry, you usually think of water-like, non-viscous products such as solutions for injecting.

Demand for small pack sizes and sample packages has recently dramatically increased. According to the Confederation of German Food Industry, this trend will still grow over the next few years.

According to a survey by statista.com, lipstick is the second most popular make-up tool with 60.2% of women in German-speaking countries aged 14 and over.

Pharmaceutical production lines are to a large extent automated. The prerequisite for a cost-efficient and effective filling line is a high-application rate or a short cycle time.

ViscoTec's dosing pumps have been successfully used for 20 years in abrasive applications, such as in the automotive, electronics, and semiconductor industries.

Viscotec presents some of the main questions you should ask prior to acquiring dosing technology, especially with abrasive media.

ViscoTec's systems for hygienic dosing and filling applications help meet hygiene requirements in the production of pharmaceuticals, food, and cosmetics.

High-pressure is often necessary for the precise dosing of small quantities of high-viscous pharmaceutical products, such as ointments, creams and gels.

ViscoTec's new hygienic dispenser aims to meet growing demands of food, pharmaceutical, and cosmetic production.

At Climator, phase change materials (PCM) are filled into various-sized tubular bags.

Conventional filling techniques in the pharmaceutical industry often see semi-solid and viscous products such as ointments, gels, and creams applied via a dosing syringe. However, the quantities required for dosing are decreasing and accuracy when filling the dosing syringe is becoming more important.

With nearly 140 years of success, Henkel holds globally leading market positions both in the consumer and industrial sectors and is well known for brands such as Persil, Schwarzkopf and Loctite.

ViscoTec pharma dispensers enable highly accurate dosing of various media with a high degree of process reliability, ranging from low to high viscosity with minimal product loss.

Due to its extensive range of services, professional consulting and high-quality technologically advanced products, ViscoTec addresses various application sectors.

When conventional filling technologies in the pharmaceutical industry reach their limits because of fluid viscosity or a stringing effect, the Pharma Dispenser Series of ViscoTec offers an effective solution.

Pharma dispenser 2VPHD12-3D provides reliable dosing of various materials.

The barrel emptying system ViscoMT-XM features a volumetric conveying pump that is based on the endless piston principle.

ViscoTec dosing and filling pump type RD-hygienic is suitable for food, pharmaceutical and cosmetic products.

The Pharma Dispenser series achieves precise and reliable dosing for a wide range of materials.

The Pharma Dispenser, with its hygienic design, improves process reliability for high-precision and repeatable filling.