Safe, effective medicines can change the world for the better. Malvern Panalytical collaborates with our customers, applying our bespoke blend of analytical expertise and in-house contract development and manufacturing services to help you make these products efficiently and cost-effectively.

When you build on firm foundations you create high-performing products with absolute confidence. Our technologies and experts answer the scientific ‘whys’ and ‘hows’, to ensure even the smallest detail is just right, while reducing risk, saving time, and avoiding costly errors.

Need to accelerate the latest blockbuster drug to market? Worried about selecting the best method to ensure quality control for a critical vaccine? Weighed down by a challenging product formulation problem? We’ll work with you, in the way that best fits your processes and needs, to develop the right way forward.

This is the power of Malvern Panalytical. Insightful, informed, and integrated support for pharmaceutical product development and manufacture. We deal with the details so you can deliver the medicines our world needs.

Analysis of materials for development and manufacturing of drugs

Malvern Panalytical’s instruments are deployed across the pharmaceutical industry for discovery, development and manufacturing applications. Whether developing new, ground-breaking drugs or generic formulations, both the time and cost associated with pharmaceutical development is significant. In addition, work-flow efficiencies may be achieved when these tools are used in conjunction with each other.

Malvern Panalytical is focused on providing well-designed, innovative analytical instruments, which follow the quality by design (QbD) ethos in the fields of drug discovery, chemical and formulation development, and pharmaceutical manufacturing.

The company understands what is involved in the development and manufacturing of a drug product and the requirements to measure the critical material attributes (CMA), as well as critical quality attributes (CQA) affecting the critical process parameters (CPP) in the manufacturing process.

Molecule discovery tools

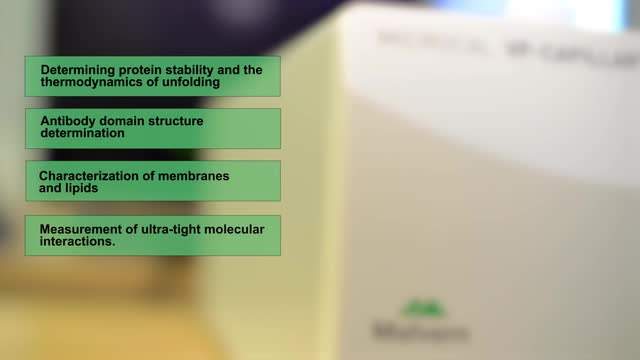

High throughput screening of large libraries of chemical compounds is the dominant technique used in early stage drug discovery, with dynamic light scattering being the optimum tool.

Being able to measure very small particle size at low concentrations, it is ideally suited as a screening tool for identifying even small levels of aggregation and potential inhibition.

Molecule optimisation with laser diffraction

In order to monitor efficacy of the suspension accurately, administering trial drug candidates in this form requires accurate, repeatable and validatable control of the active ingredient’s particle size, often on limited sample volumes.

Laser diffraction is the best tool to meet these pre-formulation requirements. This technique provides particle size distribution of nano-scale material, while also having a wide dynamic range.

Chemical development for drug delivery

When characterising bioavailability or bioequivalence of nasally administered drugs, in support of new drug applications (NDAs) or abbreviated new drug applications (ANDAs), for nasal aerosols and sprays, the US Food and Drug Administration (FDA) recommends several tests.

In cases where the active component or components are suspensions, one important attribute is the drug particle size distribution. A laser diffraction system fit for this purpose must be able to rapidly measure obscuration (optical concentration), in addition to changes in droplet size distribution and span in real-time over the life of a single actuation from the drug delivery device.

Formulation development of drugs

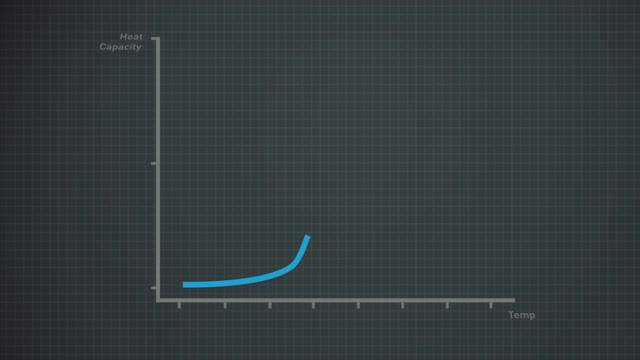

The size of a liposomal vesicle plays a pivotal role in the pharmacokinetic and pharmacodynamics attributes of chemotherapeutic drugs, with the liposome acting as a carrier of the drug to the site of action and dynamic light scattering can be an effective technique.

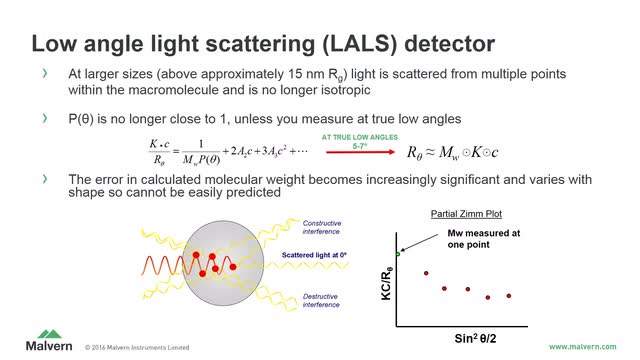

Triple-detection size exclusion chromatography (TD-SEC) can accurately characterise polymer excipient molecular size and weight and avoid incorrect determination. The conditions of a tablet coating process can be simulated using a rotational rheometer system.

The viscosity of the liquid coating is measured initially under low stress conditions to quantify its full structure, then at high shear rates to simulate spraying, and again at low stress conditions to assess the viscosity rebuild with time.

Online particle analysis for drug manufacturing

Granulation can improve the ease of handling of powder blends and prevents the segregation of fine constituents, improving consistency in subsequent process steps, principally tableting.

To improve the efficiency of the milling operation, and deliver more consistent milled particle sizes, online particle-size analysis is a solution for continuous milling monitoring and control. In addition, measurements made by the online analyser can control the process through a closed loop with the mill’s programmable logic controller (PLC).

Founded in the late-1960s as Malvern Instruments, Malvern Panalytical is now one of the world’s leading materials and biophysical characterisation companies.

Having built on a long-established reputation for innovation in particle sizing, the company today is highly respected for its technology and applications leadership in areas that range from particle, protein and macromolecule characterisation through to rheological properties measurement and into process optimisation.

Malvern Panalytical understands that when a customer chooses to invest in a Malvern Panalytical product, that customer is making a serious financial commitment. The company takes this seriously, and strives to ensure that the customer is reminded that they will receive exceptional and personalised support for the many years they will have Malvern Panalytical equipment.

Please contact Malvern Panalytical with your business enquiry.