Leak Detection Methods for Pharmaceutical Blister Packs

Detecting leaks in blister packaging has traditionally involved a destructive process, but non-destructive methods, which do not result in wasted products, have emerged as viable alternatives.

Sepha focuses on the global pharmaceutical and medical packaging market, and its main areas of expertise involve supplying innovative packaging solutions, inspection and recovery products to clients who manufacture blister packs.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Sepha focuses on the global pharmaceutical and medical packaging market, and its main areas of expertise involve supplying innovative packaging solutions, inspection and recovery products to clients who manufacture blister packs.

Our products incorporate unique, innovative and patented technologies to help meet requirements of our demanding client base. In particular, our products are chosen for their ability to improve quality assurance procedures and to reduce manufacturing costs, enabling clients to efficiently meet the stringent regulatory requirements of the industry.

Our product range incorporates three main divisions:

In 2013, Sepha joined the TASI Group of companies, becoming part of the single largest pharmaceutical test and inspection group worldwide.

Innovative, non-destructive package leak detection equipment enables our customers to improve the accuracy of their leak detection procedures and reduce costs. Our technology-based, non-destructive leak detection range is capable of detecting leaks in a wide range of pharmaceutical blister packs, induction-sealed bottles, sachets, pouches and medical device packaging. Our test process is clean and dry, allowing products that have been tested to be recovered and returned to the production line.

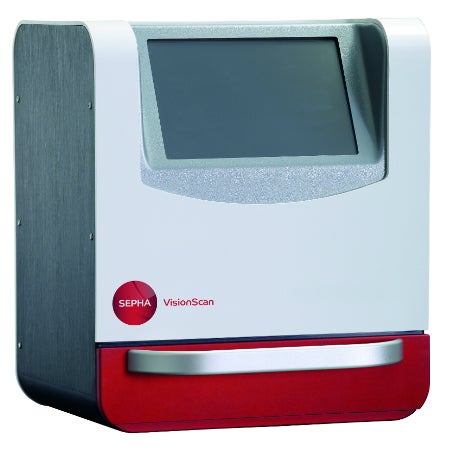

Visionscan is a tool-less, non-destructive leak detection device for pharmaceutical blister packs. Using the latest camera imaging technology, it offers modern pharmaceutical manufacturers a flexible, reliable, objective and cost-saving alternative to destructive blister pack test methods such as blue dye. Visionscan is simple to operate and requires no tooling, making it ideal for high-volume pharmaceutical manufacturers and packagers where high levels of quality control, cost reduction and multiple product changes are required.

PakScan, is a non-destructive leak tester for pouches and sachets made of flexible non-porous materials, containing solids or dry powders. It can detect holes as small as 10µm. PakScan’s test does not damage the sachets or their contents.

MediScan offers a tool-less solution for leak testing pouches and sachets. It incorporates the leak detection technology and software, developed by Sepha, that is utilised on a daily basis by top global pharma companies to ensure product integrity in their pharmaceutical production lines.

BottleScan is the latest in addition to Sepha’s product Integrity range and uses force decay technology to detect holes and weak seals in induction-sealed bottles. It tests multiple bottles simultaneously and provides an objective PASS/FAIL result for each bottle. It is tool-less, making it ideal for facilities that handle a wide range of bottle types and sizes.

Sepha are the global leader in innovation and development of pharmaceutical deblistering equipment. Our machines are used globally on a daily basis by the majority of leading pharmaceutical companies to recover valuable product from blister packs.

All models in the Press-Out range allow rapid changeover and minimum downtime with maximum hygiene and efficiency. Using minimal pressure to extract tablets and capsules ensures that foil pieces do not detach from the blisters and prevents product damage during the deblistering process. Sepha has products suitable for push-thru blisters as well as child resistant or peelable blisters

Press Out Manual, Semi-automatic and Automatic offer deblistering solutions for push-through blister packs. These machines vary in operating speed and functionality to cater to the widest range of pharmaceutical manufacturers and packagers as well as pharmacies.

Press Out Universal and Universal Mini allow valuable product to be removed from any blister pack including child resistant packs. The unique cutting action allows these models to handle packs containing fragile and friable product.

Ideal for small batches of pharmaceutical, medical or nutraceutical products from tablets and capsules to ampoules and medical devices, the EZ range is economical, time efficient and suitable for:

The compact and easy-to-use model provides a three-in-one operational flexibility and combines the convenience of a lab-scale machine with the capability of a full sized production machine.

Established in 1980, Sepha is an award-winning specialist engineering business based in Belfast, Northern Ireland.

At our Belfast HQ, we have a young, highly educated and skilled workforce, who design, develop and manufacture all our products in-house, and we export to more than 35 countries globally.

Sepha is a well-established brand in the global pharmaceutical market, known for its continuous innovation and customer-focused solutions. We have developed a strong global sales, customer service and support network in all major pharmaceutical manufacturing markets. As a result, we can include the majority of the world’s top ten pharmaceutical companies as clients.

Detecting leaks in blister packaging has traditionally involved a destructive process, but non-destructive methods, which do not result in wasted products, have emerged as viable alternatives.

Demonstrating the integrity of pharmaceutical blister packs is critically important, as any defects can affect the shelf life and efficacy of the contents.

This white paper will test the hypothesis that the VisionScan is considered non-destructive.

Sepha is delighted to announce it has partnered with Parle Global Technologies for the distribution of its specialist apparatus utilised in the production of pharmaceutical blister packs, medical devices and healthcare products, in the Indian market and neighbouring regions.

For the first time, Sepha will join agent Rieckermann at AllPack Indonesia, Jakarta in Hall D2, booth #DK007 & #DK015 from 30 October to 2 November.

Dr Dorian Dixon, packaging specialist and senior lecturer in the School of Engineering at Ulster University, has published a new white paper that confirms the Sepha VisionScan is a non-destructive method to test the integrity of pharmaceutical blister packs.

Sepha has announced that it will return to Pack Expo and join distributor Thomas Packaging in the North Hall, booth #205.

Sepha will be exhibiting at Medical Technology Ireland this September, demonstrating its newest container closure integrity testing (CCIT) and leak test solution called the Multi-Q on stand 106.

Sepha will debut two of its innovative range of non-destructive leak test machines at ProPak Asia in Bangkok.

Sepha has announced it will be launching its latest innovation, the Sepha Multi-Q at the booth of distributor Thomas Packaging.

SEPHA has announced it will be showcasing its leak testing, deblistering and packaging solutions at Achema, Frankfurt, with the VisionScan taking centre stage.

TASI TEST comprises ALPS, Bonfiglioli, and Sepha, which together provide a range of solutions across diverse global packaging leak detection markets.

Sepha has released a functional upgrade for EZ Blister, the lab scale packaging machine.

Following significant interest in the VisionScan Max prototype at Achema 2015, Sepha has taken on board industry feedback to improve its design.

Sepha has won the award for Excellence in Innovation from the UK Chamber of Commerce.

Sepha will be attending and introducing their innovative technologies at five global pharmaceutical packaging exhibitions between now and December.

The Sepha team have completed a successful Interpack, where the company launched three new technologies across each of its divisions, and carried out a significant number of product demonstrations and meetings with global pharmaceutical clients.

Three new products aimed at meeting the changing demands of global pharma-companies are being introduced by the pharmaceutical packaging equipment specialist, Sepha. They will be formally launched at Interpack, Dusseldorf, on 8-14 May.

One of the world's leading biopharmaceutical companies, Pfizer, has selected Sepha's non-destructive inspection device for blister packs, called Visionscan, as its preferred global standard for blister packaging inspection.

A new whitepaper published by Dr Dorian Dixon, a leading packaging expert at the University of Ulster in Northern Ireland has shown that VisionScan, a non-destructive seal and leak detection device for pharmaceutical blister packs, developed by the engineering firm, Sepha, can identify 100% of defective pockets across a range of blister pack types.

Sepha has secured several significant new orders from pharmaceutical multi-nationals, including Novartis, for its leak inspection machine, Visionscan.

Packaging machinery manufacturer Sepha has reported record sales of its recently extended range of non-destructive leak testing equipment for the world's pharmaceutical packaging industry

Global packaging machinery expert Sepha has developed the world's first tool-less, vision-based leak detection machine for blister-packs. Visionscan has been developed to meet growing demand from pharmaceutical blister pack manufacturers for a low-cost yet accurate and modern leak detection alter

The current industry standard of blue-dye testing the seal integrity of blister packs is not as accurate as modern Blisterscan technology available from Sepha, according to a new whitepaper published today by leading packaging expert, Dr Dorian Dixon, of the University of Ulster. In some cases, t

The specialist deblistering and leak testing company Sepha has won a major new contract to supply an international consortium involved in a ground-breaking water testing project called Aquatest. The project involves the production of a simple, hand-held water testing device. The initial

Following the launch of a new, mobile blister packing machine to its packing solutions range in May, Sepha has been delighted at the global demand created by its EZ Blister II. Since launch Sepha has generated sales for EZ Blister to India, China, Mexico, USA, UK, Ireland and across continental E

Specially commissioned research being undertaken by packaging experts at the University of Ulster's School of Engineering on behalf of the specialist machinery manufacturer Sepha has revealed that technology-based non-destructive leak detection is significantly more accurate in detecting weak sea

The increased need for pharmaceutical packaging companies to reduce waste and disposal costs in a way that minimises the impact on the environment has led to an increased demand for specialised deblistering machines, according to Sepha. The machines, called press-outs, are used to increase produc

Leading packaging machinery manufacturer Sepha has been challenging traditional thinking on leak-testing procedures through the roll-out of a global summer seminar and exhibition programme that demonstrated how its new leak-testing technology can increase competiveness and revolutionise current p

The Dundonald-based packaging machinery manufacturer, Sepha, has developed a new, mobile blister packing machine to meet demand from pharmaceutical R&D and clinical trial laboratories for a flexible, cost-effective blister-packing solution. EZ BlisterII enables labs requiring short

Packaging machinery manufacturer Sepha has launched a new, mobile blister packing machine to meet market demand for flexible short-run blister packing at minimal cost. EZ BlisterII is a compact, easy to use table-top machine for low-volume packaging solutions. It has been developed in response to

Innovative machines from the Northern Ireland manufacturing company Sepha are being used to revolutionise the way drugs are dispensed throughout the UK. The machines are called 'Press-Outs' and they enable the easy removal of drugs from their blister packs so they can then be re-blistered again i

A leak testing machine that can help Japanese based pharmaceutical manufacturers save money by using clean, dry, non-destructive testing technology will be on show for the first time at InterphexTokyo (Pharma Pack 2009). Developed by the Northern Ireland company, Sepha Ltd, the machine is called

Visionscan is a tool-less, non-destructive leak detection device for pharmaceutical blister packs.

BottleScan is a tool-less, non-destructive multi-bottle integrity tester for induction-sealed pharmaceutical bottles.

The Sepha Multi-Q is a multi-functional, nondestructive leak test and inspection system for rigid containers and flexible packaging.

PakScan is a non-destructive multi-product leak detection device for pouches, sachets, small medical devices and other flexible packs.

An automated deblistering machine for recovering low volumes of product from all blister pack types, including child-resistant packs.

Sepha provides a comprehensive range of automatic, semi-automatic and manual deblistering machines that enable the safe recovery of valuable product from all types of rejected blister pack.

The EZ Blister is a compact, customisable blister packaging machine for clinical trial laboratories and facilities requiring low-volume packaging solutions.

A compact, lab-scale package development machine, designed specifically for the medical device market where sterility maintenance and barrier protection against microbial penetration is required.

EZ Blister is a compact, customisable blister packaging machine for clinical trial laboratories and facilities requiring low-volume packaging solutions.

PressOut Universal Mini is a bench top, automated deblistering machine for recovering low volumes of pharmaceutical tablets and capsules, including child-resistant and peelable blister packs.